So, is Z’s distance on a freshly fired up printer always 5, to be lowered until the offset is calibrated properly? Trying to figure out why this machine after an upgrade bed, new heater, and micro swiss hotend, is still trash. I gave it my all since last December, dealt with Creality’s support, countless hours of PTSD-inducing aggravation and failures before I finally decided to try another printer to see how life might look like without this cancer of a product in mine. I bought an elegoo neptune 4, and a prusa mk4s - neither of which have failed me like the k2 or caused such issues. I haven’t printed on this k2 since last May and life’s been so much better. However, with this ~ $2k USD paper weight eating at my guts, I decided to try to get it working again. I realized that it was ripping the first layer up. I upgraded firmware, and I also lowered Z to the tune of -5.85 which is just about where it would be to let a 0.2mm thick paper in between with some drag. I clicked save on klipper and instead of saving -5.85 it saved it as 5.85. I clicked ‘ok’ thinking it was just a display issue - which now on restart causes a catastrophic failure because it says pr3 touch max value is +2.0. So, this hasn’t happened with any of the 4 printers here, and they’re for the most part significantly cheaper than the k2 - yet outshine it effortlessly. I didn’t come here to trash talk the k2, I’m trying to salvage this machine because it’s frustrating - but really, a $300 printer being not only more consistent but more reliable than the k2…cmon creality you should be ashamed of yourselves.

What was changed via the upgrade bed ?

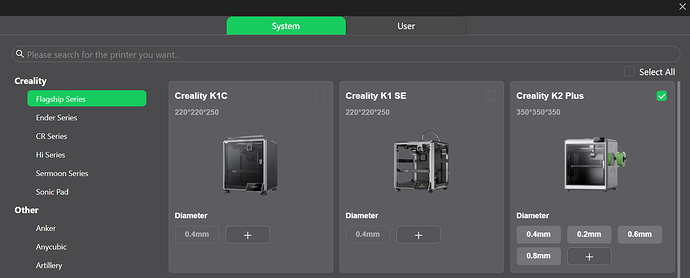

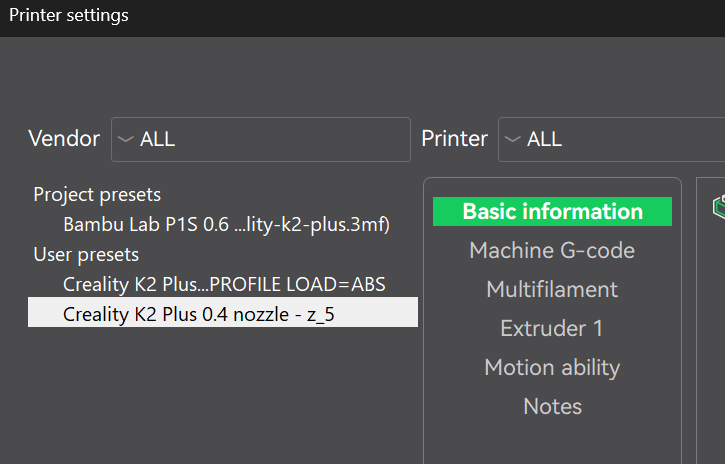

If you upload some screen shots of all your configurations, from what nozzle version pre-sets you have installed (if more than 0.4)

Basic configurations your using:

as well as extruder

then someone may be able to help you.

Also, what happens if you print a Benchy or any gcode from the USB stick , i.e not something you have sliced to rule out.

if you can’t find the USB stick the files are at the bottom of this page:

https://wiki.creality.com/en/k2-flagship-series/k2-plus

Thanks Chris. It’s a k2 plus, 0.4mm nozzle on a micro swiss hotend, IDE upgrade Bauplattform f. Creality K2 Plus - upgrade build plate | eBay bed, with a brand new heat mat from creality. I just printed up a bed mesh using 0.16mm layer height covering the entire bed around 0.25mm high to check the mesh out. If I can’t lay down even a first layer I wouldn’t even bother with a benchy to watch the spaghetti fly. Appreciate your response and eyes on this.

Why i was asking for a benchy, (or any gcode print you have not generated) is to take out the slicer / software, completely from the equation…

If you can do a firmware reset, and without using anything youve generated,sliced, print some gcode after performing all the standard initialization calibration steps…

Then if that worked your issues would be software/slicer/setup related incompatibilies with any of the hardware updates/changes…

I.e. letting the hardware just calibrate and print.

Fair enough. I’ll give it a shot and see what happens. I need to get a definitive answer on setting this Z offset because I’m not trusting that -5.85, without that being confirmed is within a reasonable range.

Ok, so youve installed an IDE build plate/mat, to improve bed mesh/probe levels…

On top of the bad default heating mat (which has been replaced)…so your heights will be totally different from the K2 defaults.

Assuming the new heating base platform has been installed correctly then,

The defaults will be for the K2 heating magnetic mat + a build plate.

But your running default base + IDE + build plate.

So 5m “higher” build plate than defaults…

What were the instructions from installing the IDE ?

Id expect you to have to configure a custom Bed / nozzle setting in the slicer software (where you choose PIE, smooth, cold etc) and tell the software you have an extra 5mm that needs to be offset for the software to generate gcode based on this new height that the ABL levels… the ABL is likely giving you a mesh based on what it thinks is the build plate… but that info isnt saved.

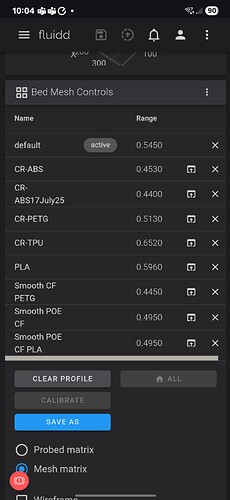

In the fluidd bed mesh page, you can save this ABL data as a profile and load it at the start of a print, but a better way forward is to create a custom base/build plate correctly offset.

Id be trying an offset of 5.005 to start with, you shouldn’t need +.85 ontop an IDE flat profile…

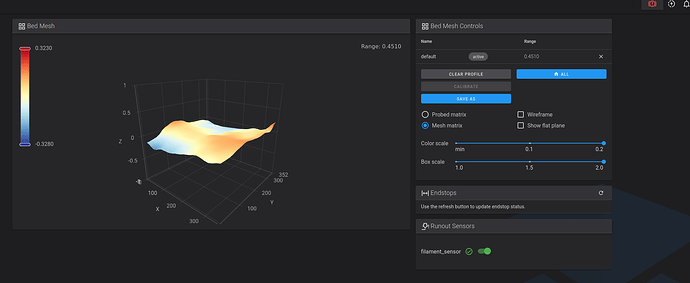

Please post your fluidd bed mesh profile…to see how flat the ABL calibrates the IDE+build plate.

As that will indicate if a) its flat b) its installed correctly.

And your firmware version…you might “also” be running one of the earlier bad versions.

Ah not positive 5.85, but negative (since it started 5mm above the plate when hitting ‘home z’

sounds like you need a custom user preset for your nozzles, ie above correctly added (as you’re running 5mm IDE higher)

whats your firmware ? if you’ve not updated recently you might be on one of the really bad ones…

suggest loading the latest which was only recently released this month.

What was your bed mesh before installing the IDE ?, .45 isnt great, if id payed that much $$$ for IDE id personally want much better levels than you get from the default stock K2…

Fyi these are my profiles from the stock setup, and while they are not great the ABL manages to compensate for a good-enough 1st layer calibration test.

I can’t remember what it was and I’m sure it’s something to do with my tuning. I can keep going via knob twisting and so forth though.

Im about to print one of these and go down that route…

As i wasnt very happy with the answer that supprt gave me on "acceptable " bed mesh variations…

Im printing 4 foot long joined together parts and .5 is realky cr*p when extrapolated over 4 feet…

oops, link didn’t paste…

one of these

FYI, I think you should do one of these K2 1st layer tests.

or

pay ??? no thanks…

3D Printer Files | 3MF File | Creality K2 First Layer Calibration | Creality Cloud

free

K2 Plus Layer Test by KIMZZOGGO - Thingiverse

and if you still can’t get good results after creating a custom nozzle profile…

then do the motor calibrations (the instructions have changes since I last had to do this to improve results)

https://wiki.creality.com/en/k2-flagship-series/k2-plus

search for service tutorials.

K2 Plus Servo Motor Calibration

K2 Plus Extrusion Servo Motor Calibration

Yep, what i did was from I forget which site, but it was one of those mesh tests I didn’t just make it . Those knobs make calibrating the bed so less painful they’re terrific and just pop right over, no hardware needed. I use one and just move it around from each to another once I finish one. No need to keep them on there or print 4 I figured after I had done just that for the longest time. ![]()

So, creality support just told me there is no way to ‘manually level’ the k2 plus, it’s only automatically leveled. Also ‘Sorry, currently the K2 plus can only select the Z-axis offset setting during the self-check process.’. I’m finding it so hard to believe, nor do I want to believe, that this printer is designed in such a way that we’re not supposed to be able to calibrate Z ourselves and set the offset. I understand you can set the offset in the slicer which is ridiculous in its own right because that’s apparently the only place to other than the start print macro. However, this thing just seems more and more like a rushed mistake that they themselves can’t get a handle on considering it’s how far out from launch and the endless issues and nightmares still exist for many. Has anyone been able to return theirs after the return window on their purchase closed? Mine was 90 days from best buy’s site, and I’m wondering if someone knows the return procedure.