As I usually do not have such (big) problems I can only make recommendations based on my workflow.

- Your print plate is far too dirty! I have the printer since ~ 12 weeks and the print plate is like new, I clean it EVERY day (with 80% IPA but you can do it also with window/glass cleaner). By the way, I never had to use glue stick or the spray so far with any PLA, PETG, ABS or ASA filament I printed so far.

- Did you look through the post First Layer Issues with textured PEI plate ? I posted there also several pictures, one where you see that I have one spot on the build plate which came just from removing previous print from build plate by hand. If I would have seen that before I would have cleaned build plate in between but luckily part was not touching this area.

- Didi you also read through Is Bed Leveling Actually Working on the Creality K2

- On your print you don’t need Raft or Brim at all! The only things what I would set is

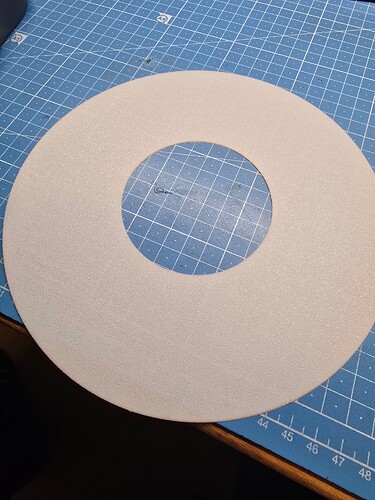

ConcentricTop and Bottom surface in the process settings because this may print better for all these small squares. I printed once a basket with similar patter in PETG as well and did not need anything more! - Did you check your board leveling with such a print TestPlateDisc.3mf (72,5 KB)?

- I just switched on my printer and took a photo of the print bed:

Because I will have to print now a big part I deceided to print this test print before to see if everything is OK. I had only PLA in CFS but started above test print (is only 10 min) just to show you how it looks for me. For some PETG I had to adjust my Z-Offset by 0.015mm or so but if you need 0.3 then bed level or bed level sensor is not right!

The result of the print: The result was not so good for PLA:

You see on middle left and back sides the ripples which mean that the nozzle need to get maybe 0.03 - 0.08 mm higher there. Overall on a real part it might not be so problematic because on bottom side of print you cannot see these problem at all:

That’s why I checked in fluidd the bed mesh:

Here I saw that i was close to the maximum 1 mm range which is twice the factor I normally have.

The back left corner is too high, it means that I could have put the print plate onto the guide corner instead of the magnetic bed?

If I re-insert build plate again, did a manual bed adjustment according to what I referred to earlier, and printed again:

Now it’s acceptable again, on both sides of this only 0.2mm high print!

Hope this example helps you to correct your problem as well!