Hi All,

New here…

Have problems with the output on the printer, see pictures, and STL file, there seems to be blobs of plastic building up on the print head and about every 5 mins it breaks off. There is also a lot of fine strands of plastic being left about.

What files or config info if any can i U/L from the Slicer to help.

Basics are bed 240 and head 75 and all defaults

Any help would be appreciated.

regards

Trevor

Holder rev1.stl (1.3 MB)

Calibrate your flowrate, I think it is too high which is why you are getting blobs. Might also be slightly damp or wrong temperature because there is some stringing.

WOW, that was a fast reply.

How do i calibrate the flow rate…

Just a push in the right direction is good, i like to try and figure out things.

Which slicer are you using? I know many of them have flowrate calibration in the start menu, personally I use Orca.

Hi Again,

Im using the one from Creality - V4.8.2-291

Thought it would be best to match with the printer.

It has an experimental area - flow rate compensation extrusion offset and flow rate factor

Perhaps i should try another slicer ?

I would give Orca a bash, it has some good/simple calibration prints to follow.

Just downloading the Orca Slicer now, will see how it goes and post back next Tuesday

P.S. Thanks for your assistance.

Retraction speed and retraction distance are other things to investigate.

Will do,

I suppose the best way is to create a small model that has various features. probably around 40mm x 40mm @ 5mm thick, on that i can check wall thickness and round surface printing as well as other options like retraction settings as you said.

Next try it with TPU, that is even harder for blobbing/temperature/stringing, same calibrations but you should be able to get great prints with the right settings.

Oki Doki,

Will be back at work next Tuesday, and try then.

Thanks again.

I recommend you to download the latest software version, Creality Print 6.0

Have you solved your problem? If not, please give me your original Gcode file and 3MF file, it is better to have the screenshot of video operation, I will ask our engineers to help you solve the problem

No the problem isnt solved yet, i still have problems of plastic blobs, not sticking down at start, lines moving on bed.

I have tried to do a bed level, and adjust the flow rate, and temperature.

Should i reload the Creality Slicer and use all default settings

Should i remove the plastic and clean the nozzle before every print.

Our Ender V3 does have the sensor for head hight.

Please help ASAP

CE3V2_sides. this fails.gcode.stl (3.3 MB)

rear input_test.this works.gcode.stl (589.3 KB)

The 2 files i have attached are both gcode files, i added the stl extension only to upload them.

The one that works was created by someone else 3 years ago, this works great, it does a 9 point check before printing, and i can see a lot of plastic being extruded prior to printing.

Mine on the other hand doesn’t work, it only checks in the middle before printing. and you can’t see any plastic being extruded prior to printing.

I dont have the original stl files for the one that works.

So going by that i can see that it is my settings on the Slicer that aren’t working correctly.

I have downloaded V6 of the Creality Slicer and will try that with default settings. But will add a brim and set the temps to 240 and 70 and see what happens.

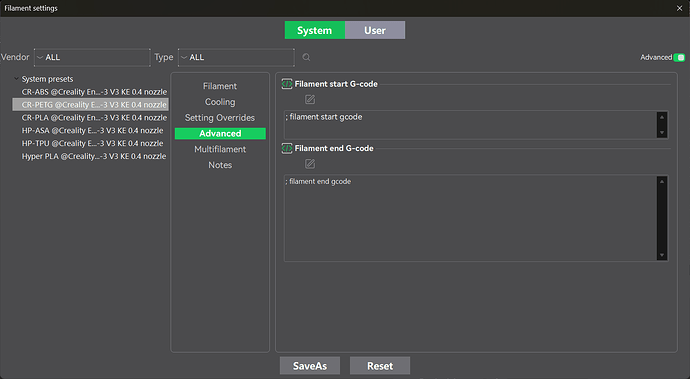

I think what i need to do is work out how to copy the header code from the good gcode file and add that to my gcode file so it does the same things prior to printing…Is there an easy way to set this up on the slicer or do i have to do it manually.

So far so good,

I added a command to do the bed leveling in 9 places, and i manually feed the plastic in at the start before it starts to print. There was still a bit of plastic strings and very small blobs, but it is working on the brim ok now.

Is there a command to pre feed some plastic using a gcode ???