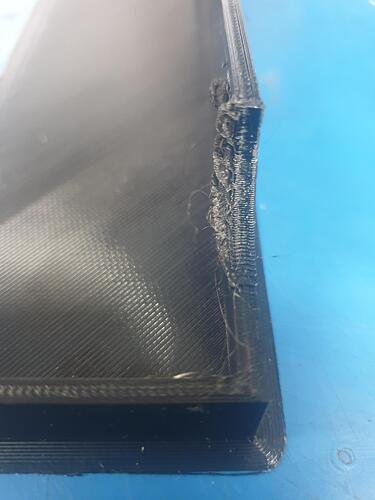

Looking at that stringing it is almost certainly damp filament. Dedicated filament driers can be cheap, the Sunlu S1 is about £30, Eryone Snail about the same, both will warm to 55°C for a number of hours to dry the roll. I prefer the Sunlu as it has a clear cover, the Snail is just as capable but the dark smoked window isn’t quite so easy to see the condensation coming off the filament. You’ll definitely need a drier if you want to print TPU, that stuff is like a sponge and strings even more than PLA when wet.

I’m still not completely convinced that it is any of uour suggestions because when i print one of the old files from 2 years ago they work 100% ok.

But i will try drying out the reel, and will slso try and tweek the temperature, anx other suggested settings. I did notice that my model when flexed you can see the seperate lines of internal print not stuck together, ill try a different fill method to fix this, but i also noticed some of my design areas were exactly were the stringy bits are. So lots to work on when i get to work in the morning.

I just started 2 models in my printers… I have 3 but only using 2 atm.

So far so good, brims both look good, no stringing as yet.

Seems that the preheat of the filament, bed leveling and a cleaned plate has sorted out the issues for now. we’ll see how its going in a couple of hours.

Thanks for all your help.

NOPE…

still the same problem, lots of stringy bits and every now and then some blobs.

So considering all the suggestions so far, has anyone got ant new ideas…

Hello Travor,

Something I have not noticed in this thread, The nozzle …

Have you tried a new nozzle ? , that could also be your fault.

If you do try it, make sure you tighten the new one correctly using a torque tool at 1.8Nm

I bought one from Aliexpress for around AU$25

It can be done without one, but you could have big problems it you get it wrong.

The other thing is the drying of the filament, it generally requires 50-60 degrees for 5 to 8 hours.

Too high and it will melt it and too low won’t do much regards getting it fully dry.

Cheers.

Appreciate the reply, but all along i keep saying that the original gcode files from 2 years ago, (Not my making) all work fine, and we use these for making production parts.

I posted the 2 gcode files so ppl can see if there is anything i can do there to fix things. So far i have added the G29 BL command to level the bed in 9 places, this did help. perhaps its also the type of slicer im using, i cant seem to find in the Orica or Creality ones were to adjust the infill rate/type.

Printing out a model now, that seems ok, just has lots of those same stringy bits all over it. So it could be flow rate, were on the slicers do i adjust that. on the older version of the Criality slicer it was easy to find but not now… were is it…

Flowrate I adjust via the Fluidd interface, it’s just a slider. You can also adjust it per filament type through the slicer.

Click on the material and then the adjust pen.

will try that, tomorrow.

Thanks.

Hi all,

Thanks for all the ideas,

I went back to basics and found some problems were caused by my bad design technique. After a model redesign i fixed a lot of the streeks in the plastic stopped, and then figured out the the streeks only happen when i am printing 2 separate areas and i get streeks between them only. Otherwise the output is perfect, the model now covers 2/3 of the plate and i have no errors regarding bed leveling. I’ll post some pictures next week of the completed model with streeks and without.

But all i need to sort out now is why it has streeks between 2 seperate areas on the model, it also seems to do it more in one direction than the other.

Any ideas on this would be appriciated perhaps around how it stops and starts the print option between those areas… lift and move then restart printing.

Seems like a retraction distance/speed problem if you get stringing between separate areas when it does a z-hop.

Thats what i was thinking, is there a global setting for this… perhaps a gcode i can change myself if needed

You can set that per filament type. Might have to calibrate the retraction speed but retraction distance I use 0.8-1.0mm

I’ll give it a go on Tuesday

Hi All.

Silly me… it is mainly a noob problem.

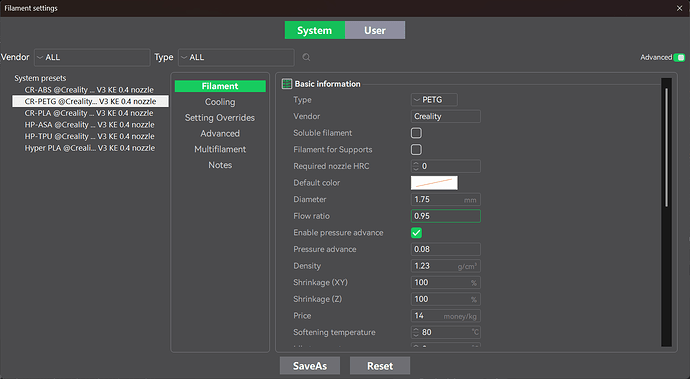

I went back to basics… first checked my filament type, and well its NOT PLA, its PETG.

So after changing that and seting the temps back to 240/65 I’m getting very good results, still have some minor stringing but i’ll do a test model to use and change some things bit by bit and see how that goes.

I’ll also print out the tower test that the Slicer can do to check the best temp to use.

I have also set my brim gap to 0mm, gives a better edge on the bottom.

And set flow ratio to 0.95,

Z HOP retraction to Spiral

And added G29 : BLT to the Gcode in the Slicer now, so no more editing the Gcode file at the moment.

Thanks to all for your help, I’ll keep you updated on my progress with my test model for adjusting settings.

Hi All,

Back again, i tried to move my model to 90 degrees and for the most part it printed ok

Only some small issues now,

Were i have put the 2 fillets it looks like its getting a bit piled up on the rear end a lot but on the front end only a little.

The 2 holes flat on the bed should be 4mm diameter, but they are almost closed up

Very minor bits of stringing and 2 very small blobs.

Does anyone think i can improve on this, please let me know.

I’m currently printing a test model to try and figure out these problems, very basic.

Test Model.stl (75.9 KB)

Side Plates rev7b.stl (113.9 KB)

I just tried the test model, and i was getting these huge blobs at the ends of the models, they should be right angle rectangles…

When looking at the slicing colors i can see that it is the seem in that spot so i’m trying a random seem now…

Uploading: 20250417_072040.jpg…

Uploading: 20250417_072049.jpg…

Setting the Seem to random has helped.

Also maybe I’m printing to fast. see the attached video…

Hi guys,

All good now…

I had to set the correct plastic type to petg

I had to set the temps for this to 70 and 240

I had to do a 9 point bed level

I had to slow the printing speed, manual edit using word to cut and paste gcode temperature settings

I used gcode header/setup from an old version

Some of these i did by editing the gcode file directly, and went back to an old version of the slicer.

My goal now is to get all of these settings pre set in the current slicer. But do at least have a good idea about gcodes and slicer setups.

Thanks to all for your help do far.