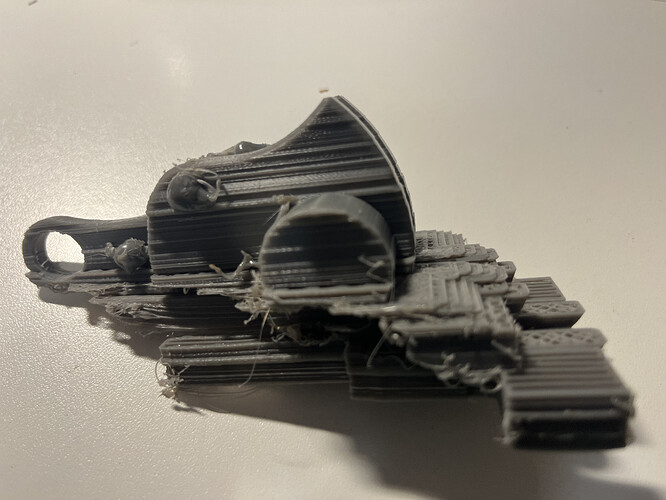

I have tried printing this (see photo) a couple of times and every time about 1/3 of the way through the print seems to slide and be ruined. I also am having trouble with the prints sticking badly to the print bed.

Which printer? I can make my V3SE do this if I use V3KE settings. Tightened belts? Trying running at half speed to see how that fairs.

It’s a V3 SE and I am using Creality slicer. I will try running at half speed. I checked belt tension prior to this attempt and it seemed good per a YouTube video I watched. There are other issues too, like the globs. I was wondering if my Z offset was too small, it’s -.75 after I reset the printer and did leveling. I think it used to be -1.5*.

Too close to the bed you might see either a rippling effect or even it will crinkle up, it will also ruin subsequent layers. Ignore the original Z offset, it can change if you re-calibrate or change nozzles or even a new bed. Just get it right for how it is now.

This might not be an appropriate place for this but I slowed down the print speed and went to print and the printer crashed with the Z probe touching the bed. I turned the printer off and the Z-probe retracted. I thought leveling was a good idea but the extruder moved down and I guess it was the Z probe moving very rapidly or it might have been stuck Z axis drive but the printer made a very rapid machine gun sort of sound. This might be an issue for Creality unless there is a fix you know of. I will search other posts too.

I also had the nozzle drag across the bed on my KE and it sounded terrible and left score marks in the bed plate. I had never manually modified the Z-Offset so this was a printer fault. I found the issue to be a loose wire in the connector from the z probe, CR Touch or BL Touch or whatever they are calling it.

Anyways, Creality replaced the nozzle, hot end, CR Touch wire harness and bed plate. Been working great ever since so huge thanks for that hook up.

For Reference the connectors, if you find that to be the problem are Molex PicoBlade connectors.

I’ve been away and back at it. Here’s a link to what it’s doing: https://studio.youtube.com/video/HLhTifIFx1g/edit

The extruder actually hit the build plate hard enough to dent it and the table underneath. The Z probe moves freely and all of the connections are tight. I tried configuration reset and after I choose the language it does it’s woodpecker thing. I found that sliding a piece of lined paper under the extruder causes it to lift to the 10mm Z position and then the heat nozzle, clean nozzle and automatic Z offset screen comes up. I have discovered that the nozzle does not heat up. It now will not go past this screen. Any help is greatly appreciated.

It’s printing again although the quality isn’t what it once was. (probably a separate issue) The problem was that the nozzle was part way unscrewed. Don’t know what caused it but I do know who replaced the nozzle recently.