Printer nozzle, ender 3 v3 ke, dragging on the table, even after automatic leveling, how to fix it? How do you manually level it?

I don’t know about manual level apart from putting a positive offset in the Z axis. On the little icon that looks like sliders you will find a Z offset, apply positive numbers until it doesn’t drag. It should remember the number until you recalibrate. I suppose you could put a piece of paper when it is trying to home to the centre but I think it will confuse things.

There is no manual level that I know of. I wish there was in addition to auto level.

If anything my KE auto level and Z is about .05 too high and I have to manually lower it. If yours is the opposite I would suggest raising your nozzle by pushing the + in the z offset and then fine tune it by using the paper method. Don’t put the paper under during calibration as it will give a wrong reading and frustrate you more (if that’s possible at this point ![]() ). Also keep in mind that this will set your z offset for the center area of the bed and (in my case) will not necessarily apply equally to the other quadrants. I have perfect center Z outward to about 60mm diagonally from lower left to upper right but even with the auto calibration (which I assumed would compensate for the highs and lows of the bed) I still have high and low areas. In other words the entire bed does not exhibit uniformity. It’s within tolerances I assume and I can successfully print first layers without any major issue but it’s definitely not completely level.

). Also keep in mind that this will set your z offset for the center area of the bed and (in my case) will not necessarily apply equally to the other quadrants. I have perfect center Z outward to about 60mm diagonally from lower left to upper right but even with the auto calibration (which I assumed would compensate for the highs and lows of the bed) I still have high and low areas. In other words the entire bed does not exhibit uniformity. It’s within tolerances I assume and I can successfully print first layers without any major issue but it’s definitely not completely level.

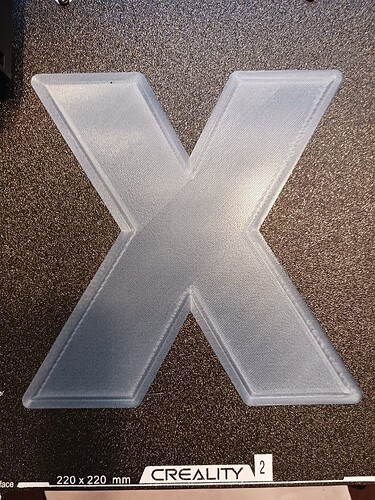

Center is perfect but note the edges specifically the upper left. (not the best lighting to tell)

Did you use the “Automatic Z Offset” function when you did your calibration ?

I had the same problem at a certain point when i got it and i literally carved a design on my PEI sheet lol ![]()

I ended up restarting the machine from factory reset and redid the whole process of adjusting and calibrating it.

I also went a bit further and did spent 3hrs adjusting the bed by sanding down the small plastic sleeve that holds the bed in place because my OFFSET was too far off from one corner to another … like -0.19 to 0.24 ++ … so i took my caliper and measured each sleeve, did an auto-leveling, micro sanded each sleeves one by one and, with each results from the display, kinda found a proper range of equal measure for the bed. Now my bed is +/- 0.08 difference and my bed test print are really nice … bed temperature will affect the distortion a lot so make sure you warm up the bed to +/- 64dg

Also, before you do a self leveling test, use the Z axis compensation with a paper sheet to find a proper pressure test on the nozzle … i am setup at -2.71.

So since then … i had no more problems but it is still not 100% straight and you need to do leveling test quite often to be sure ![]()

Hope it help

My front left corner is +0.45mm and the rear right corner is -0.36mm the other 2 corners are about-0.01mm so it has a horizontal lean but prints absolutely fine (that’s my SE same bed assembly) No plans to turn anything down in the lathe just yet but if it does go all pearshaped I might think about turning them down.

I’m having the same problem. Right out of the box my ke ran great but I got a clog while printing with some glitter infused filament and when I tried to remove the nozzle I broke the ceramic hot end. I bought a new hot end and installed it but I have had problems ever since. First filament was leaking around the heat brake and I found that some how in 2 prints totaling 3 hours the end came loose. So I fixed that then another couple prints and it starts dragging on the bed and pulling the prints off. I found that time the hole hot end had came loose from the heat sink and was wiggling around. So again dismantled, cleaned, and tightened everything up. Now I can’t get a print to run at all with out the nozzle dragging up the first layer in spots then pulling to hole print off the bed. I also have an Ender3 max first gen that I got used and it almost never fails a print. I’ve got thousands of hours on it and still running the original hot end and extruder. I have added cr touch and solid bed mounts but it’s mostly stock. This KE is really starting to tick me off.

Update

After checking everything and going over every bolt I found a few small problems that I think combined into the mess I ended up with. First off all 4 of the bed mounting bolts were loose so the bed was shifting slightly during printing. Second there is play in the extruder linear rale letting the extruder rock slightly. Third due to the bed rocking I found the auto z offset was calibrating about .15 to high. All this combined resulted in what I thout was the nozzle dragging on the bed and pulling the prints off but what was actually happening was the nozzle was to high and the first layer was lifting up after extrusion and catching on the nozzle during its next pass. I was able to tighten the bed mounts and that fixed the z offset auto detection at least close enough to get a good first layer. I can’t find any way to tighten the extruder rail bearing so it’s still floppy. After everything I finally got a full good print with really good bed adhesion.

My bedscrews and carriage screws have come loose more than once, I think I shall be grabbing some Loctite thread lock next time. Don’t think there is much you can do about the linear rail on the gantry apart from checking the hotend PCB screws are tight and the linear rail mounting is tight, there aren’t any adjustment screws as such.