Hi, I‘m having trouble with my CFS. Initially everything worked OK but now I‘m having consistent trouble with my CFS. The CFS regularly gets stuck in combination with the message that the filament might be tangled. In such case the only thing I can do is to switch off the K2 Plus and then to switch it on again, only then I’m able to retract the filament. Having a look afterwards at the retracted filament it always shows the same strange picture of damage (see attached image). The damaged part is not at the beginning of the filament but roughly 2 meters from the beginning. That is more or less exactly the lenghts between the extruder and the 4-way hub at the bottom of the CFS, so I assume there is the source od the problem. The image is showing the position only where I have cut the filament. By the way, so far I‘m using Creality HyperPLA only, nothing else. I already have opened and cleaned the „4-way filament hub“ on the bottom of the CFS several times and it seems that afterwards the CFS starts working again but a bit later the problem starts to happen again. Meanwhile I‘m really desperated and have no clue anymore what to do. And I slowly start to regret having bought that printer… Spending more time for fixing things than being able to print cannot be the right approach, honestly…

Hi, has anybody comparable problems with the CFS and maybe an idea how to solve it? Basically the CFS is unusable for me with that worse behaviour!

I have the same problem with 2 of my CFS units. I tried everything to get them to work but have had no success. I have multiple K2’s also and tried on different printers, doesn’t work on any of them, so definitely the CFS. All my other CFS work flawlessly. The problem seems to be with the CFS not pausing to allow the extruder to start and begin pulling the filament. It keeps pushing and grinds the notch in the filament. You probably hear squeaking noises in the CFS when the filament reaches the extruder. All my other CFS stop pushing when the filament reaches the extruder and then the extruder takes over and pulls the filament, then the CFS feeds more as needed. I have sent an email to support to try to get them replaced.

That basically seems to go in the same direction of my experiences. I‘m wondering whether this is a hardware or a firmware issue (or even both)?. I’ve currently made an interesting observation and I’m acting as follows. Sounds weird on the one side and isn‘t comfortable at all but seems to work for me, at least for the moment. What I‘m doing is to simply switch off the K2 Plus after having finished a print job. Some minutes later I switch the K2 Plus on again and can then start the next print job without issues. That worked for some days now. No idea whether this remains to be the case or not. But it leads me to the current assumption that it might primarily be a firmware issue?

I would think if its firmware it would happen to all CFS devices, to me it seems like a defect in some devices.

This exact same thing is happening to me - waited a few weeks for the CFS to arrive and it does this immediately!

I’m not sure this might help but I saw a Youtuber lately who fixed a problem which seems to have a similar effect like yours.

Maybe you wanna check this and see for yourself whether it might be a solution or not.

Hi, Thanks for the hint. I‘ve found that video before and gave it a try shortening the spring by 1 segment but the problem persists. Not sure whether it would help to shorten the spring by another segment but I won’t risk too much ending in a complete mess …

I have had the same issue with mine and we just got it a few weeks ago

I have the same problem myself.

The ptfe at the extruder twists when the filament arrives, forcing an angle of almost 100° and the filament is then blocked, the CFS motor forces and the cable is filed.

I didn’t get any relevant answer from the support, but I cut the 2 cm of ptfe that was twisting and the problem reappeared only once out of 40 hours of printing (and about thirty filament changes).

I hope you’ll find a solution

I have the same issues, for me the CFS has become pretty much unusable and it has wasted so much of my time, I have disassembled it, thoroughly cleaned it and shortened the spring by one circle. I still get the screeching, The CFS rewinds far too strongly and often the filament is retracted onto the spool so hard that it ends up below the surface of the already wound filament and then of course it is stuck and causes a problem trying to extrude.

I too get the damaged filament caused by the machinery and that damage does mean that the filament has more difficulty passing through the tubing and into the extruder.

I do not completely understand why the CFS has to do so much back and forth with the filament. For me it causes problems.

I think I must have one of a bad batch of CFS units.

I’m not too fussed about multi colour prints for me the benefit of the CFS would be having more than one spool of the same filament ready for automatic switchover.

I no longer think that there is anything that I can do to fix these issues once and for all.

I have the same issue.This is my second cfs for the k2 plus.The first one works without any problems.What to do to fix the problem?I am very disappointed.

I have 3 CFS and all 3 units had problems with retracting the filament and thus have been useless for its main purpose multicolor printing or automatic filament switchover. What a disppointment… Meanwhile I have sent all 3 units back for replacement. 2 new units already arrived some days ago and initially everything looked OK. But what a mess, only recently one of the 2 units started showing the same problems again. The 2nd unit still seems to be OK at the moment. The 3rd replacement unit should arrive on my side very soon and I‘m already very curious how that one will work. To be honest meanwhile I became very pessimistic especially regarding the mid and long term perspective. I’m in doubt that on the long run any of the CFS‘s will work in stable way and as expected. Presumably the CFS‘s are either of poor design or suffer from poor quality management or both. Looks like being a money grave, sadly…

The problem reappeared several times this morning… error tangled filament and twisting ptfe.

I’ve just changed the ptfe connected to the extruder for a ptfe with an inner diameter of 2.5 mm and an outer diameter of 4 mm (a ptfe I use with my MMU3 and also to connect my 2 CFS to the K2).

In testing, I found that the one supplied with the K2 offers more resistance when the filament passes through it.

I’ve just run a print and so far it’s working perfectly, wait and see.

I hope that works for you, I replaced every single piece of ptfe tubing in the cfs and the k2+ with the BBL tubing with the larger, 2.5mm, internal diameter and it has changed nothing, however I still think it was worthwhile as it should have eliminated or at least reduced one possible problem.

Hey guys, you can get the ptfe in different colours … woooo ![]()

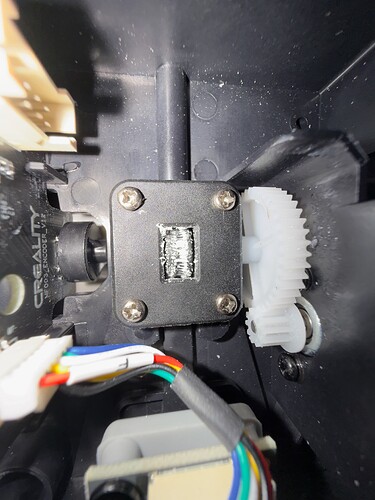

This is what happens after only one attempt to use the CFS after previously cleaning everything.

As can be seen the gear in there is stripping the filament. This happens after the retraction causes the filament to get stuck and then on the next attempted feed this happens.

I’m hoping that Creality Support have a permanent solution, we shall see.

For feedback, my 2 CFS have been working correctly since the ptfe change.

Curious, is everyone updated with the latest firmware? Did you also do a factory reset?

Had lots of trouble with the CFS when the printer arrived; updated firmware twice and several factory defaults later, and the CFS seems to be behaving.

Hi everyone! I had the same problem with my 2 CFs – they worked great at first, then suddenly started grinding filament! ![]() I saw that early video and tried cutting the spring, but that didn’t help. So I increased the spring tension by adding washers where the spring sits, and now my CFs are printing normally again!

I saw that early video and tried cutting the spring, but that didn’t help. So I increased the spring tension by adding washers where the spring sits, and now my CFs are printing normally again! ![]() Hope this works for you guys! #3DPrinting filament cfs #ProblemSolved #Fix #Printing

Hope this works for you guys! #3DPrinting filament cfs #ProblemSolved #Fix #Printing