i seen to try this what type of spacer did you use? and are you still running without issues?

are you still running with out issues?

Same problem here, tried to contact the support and no luck there. Had anyone had luck fixing the issues?

Were you able to find a solution?

Did you find a solution to the gear stripping the filament?

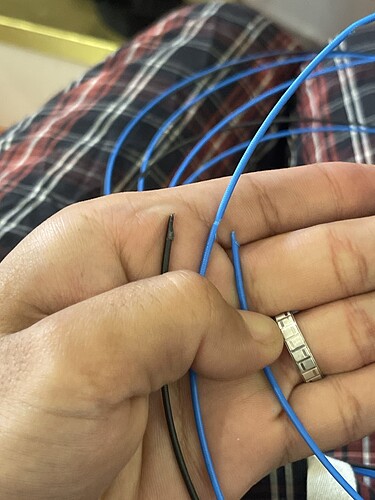

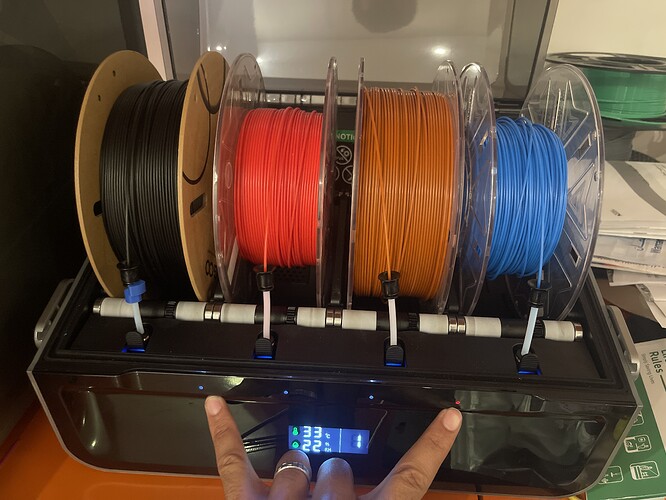

I am having the same issue but it only happens on both end slots 1&4 (A&D) the slots that have a longer distance to travel from the CFS to the hot-end. Also, the filament always stops short of the hot-end by like 2-3mm. My guess is that there is a software glitch from one of the recent updates as I have had my K2 plus since Nov. 2024 had no issues by April or March 2025 CFS issues started see images below

This looks a lot like what I was running into when the filament was constantly jamming, but for me, the jams were an order of magnitude worse for PETG, and rare with PLA. The only changes I made that affected PLA were replacing the extruder’s nozzle/heater/temperature sensor unit, replacing the extruder’s main board, and increasing the z-offset to 0.1mm. I don’t know which of these things fixed the problem, but there was evidence that the nozzle was running significantly colder than it was supposed to run, so my money is on the new nozzle.

The filament issue you are seeing is probably caused because it cannot fully engage with the extruder and it’s sensors, causing the CFS motor in the “5-way Hub” underneath to spin and eat away at your filament. The damaged filament then causes issues with subsequent feed and retractions. I have had and solved this issue too.

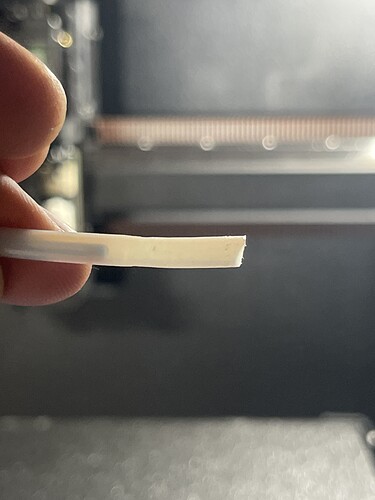

The key is to make sure your filament gets to the extruder reliably. To do this, you need to reduce as much friction as you can between the CFS and the extruder and to make sure there is enough tension to push the filament past any challenges it may encounter in its path to the extruder. I did this by replacing the PTFE tubes with high quality PFA with a 2,5mm inner diameter and I increased the compression spring tension in the CFS “5-way Hub”. I printed some 1.5mm thick spacers and placed them in the holding where the spring interfaces with the tension lever. I would not cut your spring as others have suggested because it is not really addressing the issue (it only reduces the tension and amount of your filament that is being eaten up). The tighter tension gives your filament more of a probability of reaching the header without slipping.

Finally, I also printed a mod to better align the tube as it enters the extruder, ensuring a smoother bend, and relieves the stress that has been breaking some people’s PTFE interface on the extruder. Because of this mod, I was forced to print and use a riser for the lid, but it was all well worth it because now I seem to have a reliable CFS setup with 3 units that are working well.

Hi Chris do you you have a link to your entry mod and the riser you mentioned. Of all the answers to these issues yours seems the most plausible!

This is what I am using for the entry mod. It modifies the adaptor for the chain that attaches to the extruder head. 3D Printer Files | 3MF File | K2 plus bowden tube saver | Creality Cloud

This is the riser I am using. It is simple with no vents, so I still remove the lid for things like PLA, but it works for me. There are a lot of risers out there, so you may find one with vents if that is what you are looking for. 3D Printer Files | 3MF File | Creality K2 Plus lid riser | Creality Cloud

Finally, I just used a disk testing primitive in creality print (right click on a blank plate and select “Add testing primitive”) for the spacers I made and just made the disk 7.9mm x 7.9mm x 1.5mm using the scaling feature which seems to work well.

I printed everything in PETG because of heat concerns.

The machine logic does not pass that sensor state to the CFS. Instead it uses the sensor on the CFS push motor to know when the filament is halted by the extruder and then stops the CFS push motor. If the motor gear is slipping on the filament it never gets the signal to stop itself. This is the purpose of the magnetic sensor on the CFS push motor.

I took apart the gears on the bottom CFS push motor, cleaned out all the filament dust thoroughly and then used some washers where the spring goes to add more “grab” so that the motor is stopped when the filament is stopped by the extruder. My problem disappeared completely after this.

To the OP:

I had this exact problem as you describe. I would disassemble and clean it but the problem kept returning. My other CFS consistently worked great.

It was driving me crazy because I would watch the filament go all the way to the extruder and turn on the filament sensor light, but the CFS would never stop pushing until it wore the exact mark into the filament that your picture shows. I thought that the logic should stop the filament as soon as it hit that sensor in the extruder. I finally realized that this is not the way the machine works.

That was pretty much my conclusion too. I spent a whole afternoon looking at the CFS parts and diagnosing the issue. Only difference is I printed a 1.5mm spacer to use instead of using a washer to increase the tension, but results were the same. My CFS array is working well now.

Have had the same problem for 2 days. The problem for me was at least i think it was because dont have the problem anymore. When the roller under the cfs start to spin the front top mechanisme dont release the fillament and the roller eats in the fillament. So when that have happened most of the time the cfs retract the fillament back to the roll and the second time it get jammed. First i have shorten the spring from the roller under the cfs that did not work. then i have used 2 washers to make the spring stiff that worked for the creality fillaments but not the sunlu then i have used a empty creality rol to set my sunlu fillament on that helped i little more. Then i have opend the cfs and reset al the mechanisms to the same spot also the motors al the same spot. Then started everything up then activated the fillament synchroniseren that takes a minute when you power on( because i had it turned off) then powered the printer off and again on to let the cfs synchronise. Forget that i also had a problem with the fillament detector under the cfs there was some pla under the little iron feeler think it was because a have destroyed half kilo pla for testing/ repairing. For now everything works hope my experience can help you in any way.

Hey you two, it seems I have the same issue (filament reaching the extruder, led powering on to tell the filament has been detected but then the CFS keeps “forcing” and ends up eating a chunk of filament).

Can you please share a picture or something to help me locate where you put the “washers where the spring goes to add more “grab””.

I don’t really understand where it is, sorry English is not my first language.

Thanks in advance.

Have a great day.

creality print (6.2.1.3044)

win10 to printer by usb flash (gcode)

creality hi (1.1.0.48)

cfs1(1.1.3)

cfs2(1.1.3)

cfs3(1.1.3)

cfs4(1.1.3)

(cfs - edit - creality - pla - crpla/crsilk 190° - 240° pressure advance 0.04mm)

problem:

when cfs loading filament by gcode, it feed filament too hard whith no reaction on buffers end switch, so cfs red led blinks twise/sec (motor overcurrent protection indication🤔),

sometimes at this moment cfs feeding wheel make wierd noise and eat filament, then stop printing (printing without filament error), after resuming print, it has lost layers…

if i paused printing and unload/load another color from printer menu (manually, not by gcode), it works perfectly - it feed filament untill buffers endswitch

tryed it on different cfs, the same problem…

some kind firmware fail, tryen on five cfs, the same - looks like sometimes(randomly) 5way hub bldc motor feed too hard/much ignoring endswitch and stop feed by overcurrent error(red led blinks twise/sec)

cfs use ms8828 3phase driver IC + bldc hall motor + mt6826 encoder under 32f303arm and i think someting goes wrong with firmware because it is all new stuff

max current of 8828 depends of Rsense, in stock it has 2x0.5r in parallel - 0.25r - about 2.5a, by removing one of Rsense max current drops to 1.3a, so it has not enough power to eat filament, it just catch error, but continue print

strange solution, but it works, anyway waiting for answer from creality, i’m sure thay will solve this bug

i tested all endswitches, it’s ok

I don’t have access to my CFS’s right now to take pictures as I am moving and they are boxed up. But this youtube video shows where the spring is that I placed the spacer at. Don’t cut the spring like the video says though – add the spacer instead.

Its inside the 4-way splitter. Its not that really hard to remove. Then you need to open the 4-way splitter to get to the spring. I am on holiday at the moment when i am at home i can sent pictures from the inside bit i see there is already a link shared from a YouTube video. When you are a little bit technical i think its not problem to open.

Thank’s both of you ! I should be able to locate it ![]()

I’m surprised because adding a washer means that there will be more tension on the spring if i’m not mistaken o_o

I’ll try !

If by anycase you have printed the washer I’m glad to have the STL, if not I will find something. Thanks ![]()