Heard about it in the late 70’s early 80’s, could get it from the chemists back then.

They have emailed me back informing that they are launching a PP adhesive at the end of this year.

Hello Iron3Dad,

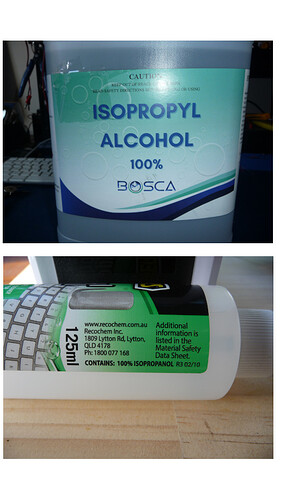

We don’t muck around in Australia, it’s 100% and it is BIGGER

and the guys that produce it are named Bruce.

Cheers.

Doesn’t that leave a coating of PTFE or silicone? Much like I won’t let the cleaning lady near my bed she is not allowed to polish my bed (furniture polish MrSheen), as nice as she is, it isn’t a good thing to put on your build plate.

When I got my first 3D printer around 9 years ago (A Prusa Mk 2) I watched a getting started video by Josef Prusa, who showed how to clean down the build plate before every print, using some supermarket window cleaner (the cheap stuff) sprayed onto a sheet of kitchen roll. I’ve done this ever since and, especially with PEI plates, it works like a charm. Cleans grease off the plate leaving a “neutral” surface which neither holds too tight nor too loose. I’ve tried other methods since, but always come back to the supermarket window cleaner - why pay more???!!

Hello @Bonfireman ,

I saw that also and wondered if it was maybe a mistake.

WD40 will put down an oily film that will then need some doing to get off again, mind you, it will certainly be clean.

I wash my build plate with a small amount of dishwasher liquid and water maybe after say 10 prints or so. But I wipe it down with isopropyl alcohol each print … and then have a drink of IPA ![]()

i can agree with that, I think it is mostly vinegar, best way to clean windows vinegar and paper. Missus hates it when I clean the windscreen but at least it is properly clean. Can I print on a windscreen? Now there is a challenge. Depending on country Fairy/Dawn/Dreft/Yar are the same Proctor and Gamble washing up liquid, best for washing build plates.

is not the intention to spray wd40 on your build plate. meant to say that 3dflac works so well that if you spray your plate with wd40 and then spray 3dflac on it, even most prints will stick. was meant sarcastically. sorry language barrier i think.

Hi,

No problem, it was basically just giggles anyway I think.

Cheers.

Why not, how about the splat version of Wile E Coyote ?

Cheers.

Update: here is a test print I did last night with eSun PLA+, using settings from https://www.esun3d.com/uploads/eSUN-High-Speed-Printing-Filament-Parameters.pdf for the P1P (I figured it would be a closest match). I also left the top glass off, enabled small area flow compensation (defaults), and enabled ironing with the following settings;

ironing type: all top surfaces

pattern: rectlinear

speed: 30mm/s

flow: 10%

spacing: 0.15

angle: 90

I have the same problem. Start a print. First calibration ect ect. The first layer is like sandpaper. A complete fail.

Manual z height to .345mm up and the print is ok.

A benchy from the printer default does print ok. No need for a z height adjustment.

But what caused this?