Hey there!

I am experiencing a weird issue with my two Ender 3 V3 SE.

Recently, I started printing my current project, a hopefully improved version of a board game I want to gift away, but I ran into two issues with the visually identical printers.

I sliced the files once and copied them onto two identical SD-Cards - so far no issue.

But one of the printers will print at a good quality, but much slower than the second one, which in turn produces a X or Y-axis shift on almost every single print. Both are working with the exact same files.

I had to replace the mainboards a few weeks ago due to the printers damaging my SD cards, but I thought they were both printing reasonably well. Some failed prints can happen. But those layer shifts on the one printer are ruining big prints, while the other printer needs twice as long for the exact same print.

I naturally checked the two belts, but they seem to be under good tension - low hum after plucking them if that is anything to go by. The belts on the “slower” printer feel the same to me.

So… what is going on here?

I hope you can help me with this one.

As you can see, I named the file with the duration and cost of the print. It is supposed to take 9 hours, rounded up from 8 hours, 57min.

The left printer sits at 22% after 5 hours, 28 minutes, the right one sits at 79% after 5 hours, 31 minutes.

So both have been started one after the other, both have the exact same file, but they are producing significantly different prints:

- Unexpectedly slow but high quality

- Unexpectedly fast but poor quality and layer shift issues.

Doing the math, the right printer would do the file in 7 hours, or 78,78% of the expected time.

The left printer would do the same file in 24 hours, or 256% of the expected time.

Clearly, the left printer is being too slow and the right one too fast to produce good results. But they have the same mainboard and the same settings other than the Z-Offset.

Do you have any idea what kind of issue I am dealing with here?

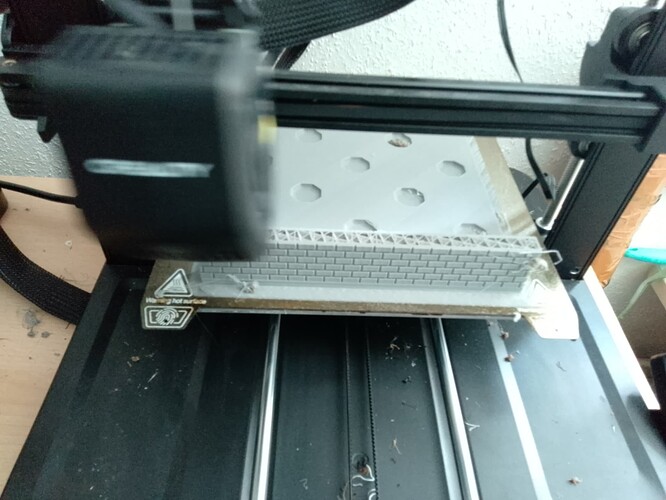

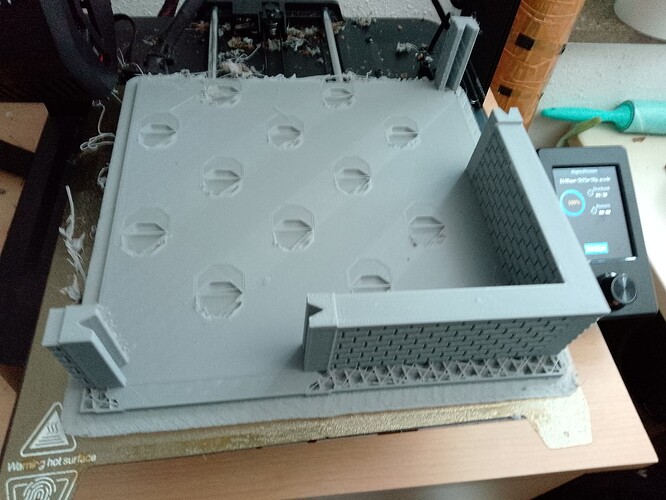

Here are two pictures to show the layer shift. The faster printer layer shifts once almost every print, either 1mm, which would be workable or 1cm plus, which is entirely unacceptable. Both X and Y are affected.

Identical machines, identical files, but print differently? Most odd. Are you certain that both machines are running the same firmware, the speed difference might be down to that. I would be having the bottom cover off to check that the mainboards are the same.

I did upload the same firmware to both printers. But I will try to do it again.

Both the Mainboard and the Screen.

As it is now, the right machine is only producing failed prints…

My prior experience with layer shifts has always been a loose belt.

1 Like

I tightened the belt and updated the firmware. Currently testing a 3h print.

Hopefully it will work out this time.

I used my oldest, most abused PLA filament to do 3 prints on the faster, unreliable machine. All of them ended without any layer shift. I did a more important print afterwards, which has had a layer shift in both x and y, both of them about 1cm, even though I checked for damage, loosened, moved and tightened both belts. Even cleaned the whole printer.

Fixing the layer shift and speed issues is on a hold for now, as the printer started getting cr touch errors on top of the shifts.

Right now, I brute forced a print by pulling on and rotating the sensor pin, but whether the print started due to this or plain luck, I have no idea.

Next step will be flashing the much too slow printer with the software, even though it has the most recent version already on it.

All of this feels really, really bothersome…

Oookay. More bothersome stuff.

Looked up the CR-Touch error message. Some of the advise I found was to clean the touch sensor with something like WD40 cleaner spray, as it can become sticky. I did not have that on hand, not even isopropanol and such, so I checked other possible solutions.

The creality website advices to check all cables for the CR-Touch module, but I ran into an issue doing that straight away. Out of the three screws securing the heatend cover, only two could be turned by the right sized Allen key. The left one was already too round to be loosened. I never touched any of these screws! How can any one of them be in this shape?

I have to admit, I am getting slightly pissed of with this machine. There is something seriously wrong with the slow one as well, but at least it churns out good prints. This one is giving me layer shifts, blobs and stringing, all kinds of issue - if I can force it to start in the first bit! And now I need to drill open the heatend cover to check if the most likely hot glued connectors came loose?

Hey there!

My last few prints on the machine were really good. There was always, every single time, an issue with the sensor. Pulling it out manually works sometimes. Spinning it slightly does as well. All in all every print now requires a warm up of fiddling with the sensor for several minutes, starting the print again and again until it finally does its job of measuring the z distance.

I will drill open the “damaged-by-factory” screw next week and clean the sensor as well. Also, I likely need to reattach the sensor, since it is tilted at a slight angle. 10°, maybe less. This could likely cause the issue. Some kind of residue on the sensor itself could as well. Or the cable coming loose, which I think is very unlikely since it was hot glued in place.

As for the print quality… I am experiencing some stringing, though I never had perfect prints on that specific filament, so I expected that.

There are no longer shifts in either x or y axis, even though I did not change anything after addressing belt tension two weeks ago. And I certainly had shifted prints after that, albeit only two.

My current print is 18 hours at 0,1mm layer height. Not a single tiny layer shift so far, at 16 hours.

If I get to fix the sensor, the printer will be perfect again.

After addressing the sensor, I will do something about the slow printer. It, too, had 2 sensor errors so far, but those were one time only. And it’s slow print time didn’t exactly bother me too much so far.

Should be able to tweak the metal mounting bracket to straighten that up. Cables coming loose, even though they are hot-melt glued in place has happened, check it anyway.

Stringing will be doing the calibration checks but also might a case of changing the extruder temp up/down. Managed to get 2 printers to happily run PETG/TPU without stringing, the others just string, even if only a little bit, no matter what I try.

Curing/losing the layer shifts is great, sound like it is slightly random.

Did all kinds of calibration on the slower one of the two Ender 3 V3 SE.

Adapted first layer height, flow rate, filament shrinkage compensation, and everything else I could think of.

Ran every discovery through the slicer (other than the skew I found out about, which can only be fixed by rather complicated means I have no prior experience in). And the prints are looking much better now.

As for the faster printer… I woke up to a messed up 100g/18hour print, that had once again a single, big layer shift (~1cm) at a critical height, turning all important parts of the print unusable.

I rechecked the belt tension, but it seems to be entirely fine. Has the same tension as any other belt on my 4 FDM printers. I switched to smaller batches of printing for now (5+5 pieces instead of 20+20), cutting down the print time and hopefully avoiding another big loss, since I am very close to running out of that specific filament.

Once I am finished with that project (I have 90 out of 120 parts finished) I will run that printer through the same 2 days of testing the other printer had to go through, including loosening and retensioning the belt. Will take a good look at the belts while I am at it. Still, I think there is something else causing the layer shifts, especially when it is only a single one each print.

I am also changing the slicer from reality slicer + cura to orca slicer, to check if that makes any difference. Already ran the calibration of the other printer using that software. Still, I need to drill that printhead open and check for the cable and sensor. Those have to be checked/fixed no matter what, since the layer shift and the sensor are two separate issues.

I will keep this one updated.

In hindsight, and to be entirely fair, I burned a fuse while turning on the lights in the hobby room. The printer was out of electricity for 20 seconds or so, and it allowed me to resume to the print afterwards. Within seconds, it was printing again, and it looked like everything was fine. But in hindsight, I might just not have seen the layer shift that likely happened at that exact time.

A printer loosing its position due to power loss is to be expected, and I don’t think it zeroed its x and y axis before resuming printing. So… unfortunate, but that issue cannot be blamed on the printer but rather the ceiling lamp.

As for the z sensor, I will open the print head today or tomorrow.

Hi there, were you finally able to find a solution for the slow printer? I am in a similar situation. Bought 2 V3 SEs, one is running very fast while the other is running much slower with the same file. Print quality is actually better on the faster one, slight layer shifts on the slower one on the bottom layers.

I never found the solution to this one. My printer just stopped being slow after I ran the same file through the same slicer again days later.

I have absolutely no idea what went wrong with the first file, as I copied its gcode unchanged onto two sd cards of the same size and manufacturer.

My printers had a certain hunger for SD cards, destroying them by - according to the support - overcharging them due to a faulty Mainboard. I had replaced the Mainboards, but the issue prevailed, which is why I bought a raspberry pi to control my three active printers with.

Maybe, just maybe, the faulty Mainboard of the left Maschine combined with a slightly damaged SD card caused the difference in speed, but I could never replicate it.

The printer prints at expected speeds now, finishing the same print at the same time than its neighbour. There is some z-axis shifting that is stronger at the back right and best at front left, but the Maschine ran perfectly until just a few days ago.

So… sorry…

I cannot help you with this one.

Try to upgrade your firmware if it isn’t up to date.

And if it is not, try a different slicer like Orca, Creality Slicer or Cura, depending on what you used before. Slice the same file and maybe swap the SD cards between the machines.

The mainboard might be at fault as well, but it will be very hard to check it for damage.

Have you compared the actual settings on both printers.

Stock firmware : Control —> Motion

Compare each under Max Speed, Max Acceleration & Steps per mm