I recently bought a Creality Ender-3 V3 KE from the [official] Creality Refurbished eBay store. Ever since I bought the printer, a faint “grinding noise” comes from X-Axis movement. It is more mild when you use the display but it is still there. If you move it faster, it will make a “screech” like sound. I have tried to change the tension multiple times. I’ve attached two videos, one with filament, and one without. Any tips? Thanks!

Sorry for the background noise in the video!

LINKS: https://drive.google.com/file/d/1N0Ky12MpzGH2rXRNV7iSjViYaRbXIQ_Q/view?usp=sharing, https://drive.google.com/file/d/1e9N3bWjQ2wOaD2T50en02nnQTDl0NYwX/view?usp=sharing

FILAMENT: Creality Ender PLA Value Pack [red] @ 40-80mm/s

Have you tried lubricating the linear rail bearings?

No, I haven’t. This is my first 3D printer. What lube should I use, and where exactly would I put it? Thanks!

Hi

I use “Super Lube” multi purpose synthetic grease.

It needs to go into the groove both sides of the linear rail top surface.

Put a small amount into the groove and manually move the extruder head along. apply more grease then move the opposite way. use a clean lint free cloth to remove any excess grease.

The ballbearing races on these can fail, have you seen any tiny silver balls?

Hey, Thanks for the reply! Just a couple of questions.

- I live with birds, and therefore I open windows during printing- does the synthetic grease produce any fumes in the long term, or just a small amount during application?

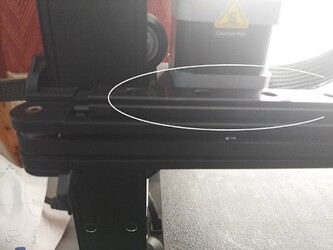

- By the groove, do you mean the small circular nail holes at the top, the small rectangular hole to the left side, the actual GROOVE on the rail, or something else? [see the images below to see what I’m referring to]

Also, I have not seen any tiny silver balls, however, at the bearing on the LEFT side that holds the belt, there were some tiny black pieces that I cleaned off.

Thanks!

UPDATE: 10/13/25

Can this be belt rub as seen on this printables post? This is exactly what happens on the bearings, with those tiny black pieces included!

Images:

Hi

Firstly I am not aware that the grease gives off any toxic fumes, it will never get hot enough to break down.

The groove referred to is the one shown in your 3rd picture.

The black pieces are probably parts of the belt that have rubbed off.

I have a SE version with a linear rail mod, so a slightly different printhead, however check your belt tension to reduce any slack in the belt. See google for instructions on how to tension KE belts.

Alright, thanks so much! I will post my results soon

Sadly, that didn’t fix anything. (did help it run smoother though). I also changed the belt tension, same result… Looks like belt rub. When I move the print head left and right, the belt slowly goes down (aka, it goes from the middle to the lower part of the bearing)… I think I might print those spacers I mentioned above.

Any other tips? Cheers!

EDIT: I found another model that works better because it doesn’t need a full disassembly. Link is here

Note: I did make the following modifications to the 3D printer:

- Lubed the X,Y,Z axis

- Changed build plate to a double sided, textured PEO and Smooth PEI one (235x235mm)

- Mounted the spool on the side and made some accessories for that