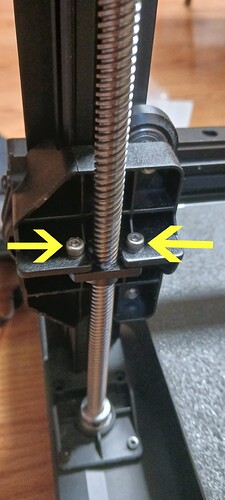

The screws that hold the lead screw nuts should not be tight. Tighten them then back them off a quarter/half turn, smooths out excess movement from the nut/leadscrew by letting it move around a bit.

I’m assuming you mean these?:

I think I did tighten them at some point and did back off but maybe not enough(?). Worth a shot. I’m assuming there is no specific torque setting and it’s just “by feel”? Should there be any play of the rod at all?

That’s the screws. There shouldn’t be any play on the leadscrew on the stepper motor side. The other one I get about 3mm when I lift it but it drops back down into place.

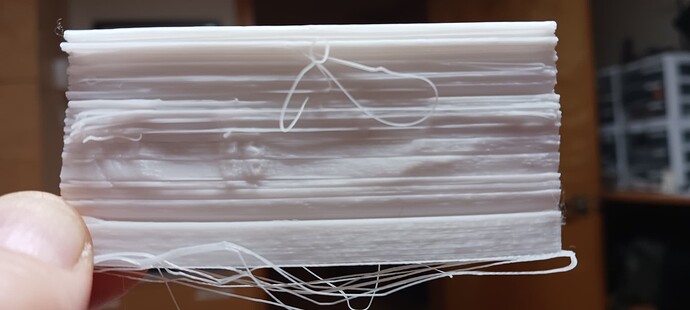

I printed this on my Ender3 v2 some time ago. You can see up the side of the model that it has identical, regular layer shifts. I found out that the motherboard compartment with its mess of wires was disrupting the stepper driver airflow. I straightened up the wires, printed a replacement compartment cover from an stl found on Thingiverse and bought a larger diameter fan in a slim design that fit the new cover. I haven’t had a problem since.

I reset both sets of screws to have the slightest of resistance/torque and…

DRUM ROLL…

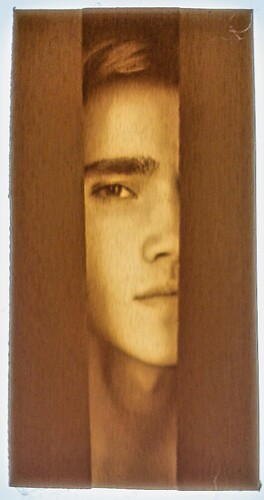

SUCCESS!!! After adjusting the screws.

Before adjusting the screws.

I must have tightened them and completely forgot about it (it’s been one crazy month). My sincerest thanks to everyone for their help and of course to @Bonfireman for (literally) setting me “straight”. Thank you again!

It’s only 1 print but I suspect that was the exact issue. Time to do a couple of more tests.

Until the next “disaster” which attempts to lay siege on my fortitude…

Cheers!

Looking forward to it lol, glad you are sorted.