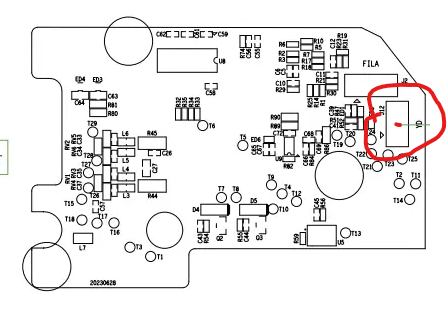

What is the part that plugs in here? I can only find one mention of it searching. Diagram shows is a height alignment sensor. I can not find this part searching for it. The wires broke off. I am considering trying to solder them back on but I would just feel better buying a while new piece

That is the load cell/ strain gauge.

It does the automatic zoffset measurement my pressing the nozzle against the bed. It then reads the load, same as a kitchen weight scale, to determine when it touches.

Frankly, you are better off leaving the wires off. The auto zoffset is proven to be unreliable.

You then do the zoffset the old school way, only when you change the nozzle or hotend. “Paper test and baby steps”.

The auto calibration at the start of the print (locally on the screen) needs to be turned off every time. Or print straight from the slicer.

I can send you more info if needed.

Otherwise you need to try a warranty claim, since it cannot be fixed and not available as a spare part.

This part is called the piezoelectric ceramic bu Creality and they have just recently sent me a new one because of issues with my printer

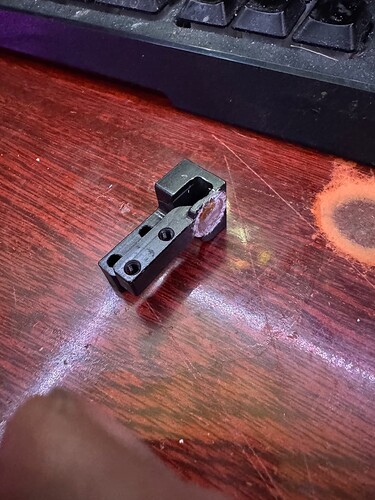

This is ridiculous. I managed to solder the wires and it worked for a bit but now the piece snapped in half after the nozzle dragged on the bed. This piece is also the mount for the hot-end so now my printer is a paper weight. I have emailed CS support, messaged on facebook, whatsapp and called their customer support number (no answer). I am not getting any response out of this company. I have seen so many others with this same defect during my research, how do they not sell this part in the parts mall, more-so when they actually made a video on how to replace it. I will never buy one of their products again and if I could return this one I would.

I am again waiting for new parts for my printer but am expecting a delay in delivery because of Chinese New Year. I can’t even get a Chinese take away.

A delay in delivery i could accept, but flat out not being able to get anyone to respond. Thats not acceptable.

Ditch the automatic zoffset which uses the load cell on the bracket.

It’s known to be unreliable and @CREALITY has chosen to ignore our complaints.

Do the old school “paper test” and “baby steps” to set the zoffset, only when needed.

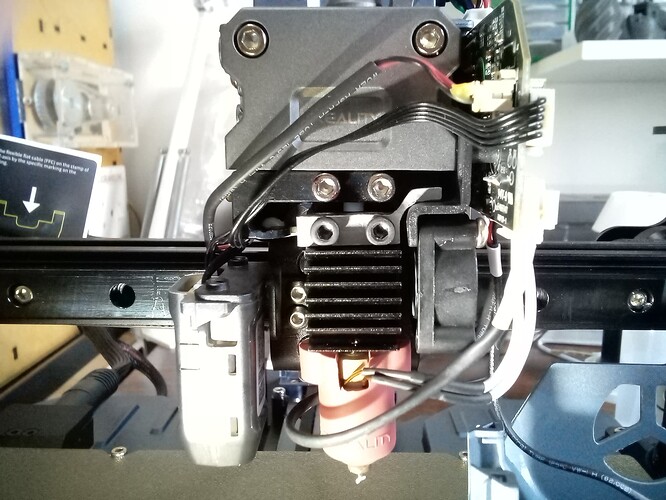

Make this out of 3mm aluminum flat bar.

It stops the bracket form flexing the hotend down under high extrusion pressure/speed.

You need 2 screws that are 5mm longer than the original - not any longer.

Only a saw, 3mm drill and round file needed.

it looks like in the picture you are still using the original “bracket”. mine is completely snapped in half at the thinnest part so i cant mount the hot-end at all. maybe i am seeing things wrong. right now I have some high temp JB weld and am trying to fix the piece enough to do what you are suggesting with the manual z offset setting.

To make sure the printer does not do an automatic zoffset while the load cell itself or it’s wires is missing, comment out the [prtouch_v2] and [z_compensate] sections in printer.cfg.

Then you can make the temporary bracket a solid piece.

so far things are looking good. this stuff takes 24 hours to fully dry so ill try this tomorrow. Thanks for the advice.

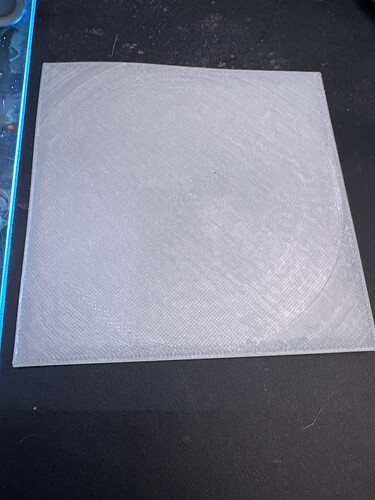

Well I got the bracket fixed. It’s not breaking again. Lol. I got mainsail installed and edited my printer.cfg. Manually set the z-offset and I got a good basic print. Now to try something more complicated.