A few times now I’ve heard a “zip” noise from the printer when there were some really fast movements. This cardboard spool of Eryone matte finish had a tiny ding in the brim but I straightened it out. I noticed the texture of the filament is a bit courser than others. Has anyone experienced this?

Added the video, was able to catch it and it happens at about the same place every time and similar/same movement. It’s worth mentioning that all of the other sudden/jarring/jagged/insane movements don’t cause this, just that one in that spot each time.

@frankjoke perhaps something you might be able to spot considering your expertise so far?

Just an update: I ran the same prints, all exact parameters and details of the entire print (software and filament) but went directly to the spool. Not a single sound similar to what is in the video. I’m going to be checking the buffer as well as all parts of the CFS hub beneath it in hopes to determine what’s causing this issue.

Kris,

I use also a lot of matte PLA and have several spools or Eryone as well. Matte PLA has a lot more friction within PTFE tubes and it’s much harder for the extruder/CFS to push/pull especially where PTFE is heavily bent.

I exchanged already my tubes once because I could not print some matte filament anymore, either CFS could not retract or filament did not reach extruder.

Thanks a lot for chiming in there. So that noise, you would say it’s ok/expected/healthy? I ordered a couple of new gears just in case because something like that, makes me paranoid that eventually things are going to get stripped and stop working as well as they need to for this.I’m a HUGE fan of matte and love it, I buy just about everything-matte all filaments when possible. So, I don’t see this improving or going away on its own ![]()

It makes sense that the feed rollers want to move the matte filament faster than friction in the worn PTFE guide tubes will allow, causing the noise when the feed rollers slip; Just curious—how much mileage do you get out of the PTFE tubes before they need replacement with the matte filament?

I exchanged after ~500h of printing all different materials.

I posted it on K2+CFS modifications: The extruder and CFS tubes & connections what I did. In the meantime I exchanged also the tubes within my first CFS (the second I have only a view weeks when there was a 15% discount on Amazon) recently and the tube between the CFS exit and buffer enter because it was too long and some filament did push too much into PTFE wall so it bent as well.

When writing this I just printed a part of a ‘magic box trick’ for my other grandson in extrudr NX2 matte black filament.

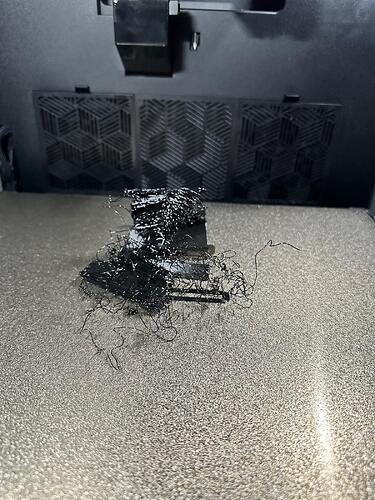

Whatever it’s doing that the zipping noise is occuring, is now more frequent and in a different area and motion. Something is definitely bad here with a gear somewhere. Quite frustrating. It just caused some feed issues that affected extrusion.