I removed and checked the filament sensor, used a fine file to smooth/enlarge the hole a tiny bit.

re-assembled everything, made several passes with a bit of filament to check that the spring was working as intended, all good. (so far…)

The actual opening for the spring isn’t even round in my case, slightly oval, but this ought to be fixed now.

I also enlarged slightly the hole for the LED and stuck a bit of transparent filament, which makes the LED a lot more visible

I hope the filament replacements will go well now.

5 changes so far, no issue ![]()

edit: 2h and countless changes, all good

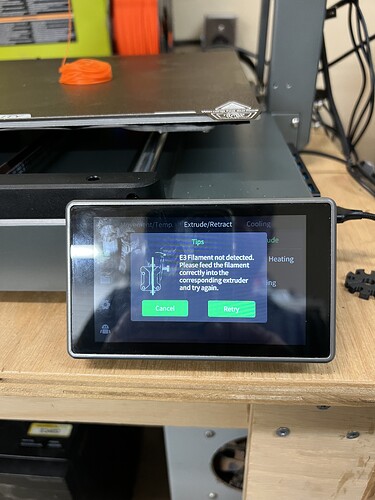

Well I finally got it to work partially. I had to install mainsail and use it to set up the serial path for kcm and chromahead. Units bought directly from coprint must be different because the kit is meant to work on any kipper machine. Now I have another problem when I extrude it squirts filament for a long period of time then shows an error saying filament not detected

check the filament sensor ?

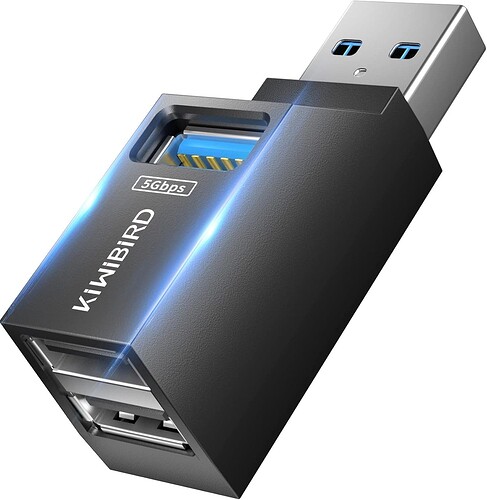

I also bought it from Coprin, and I didn’t do anything, I just installed the firmware and the Orca slicer. Fluid is available from the Orca slicer, which is the same as Mainsail, only called Fluid. However, I didn’t have to set anything here either. And I only use it because I can see what the printer is doing through the camera. I assembled it and it worked immediately. It will only work with the Orca slicer, other slicers don’t have the Coprint profile. It can’t print models that come with the printer, such as the Nebula console, it says the same thing. If you send it to the printer from Orca, it works. This may be because the Chromahead retracts the filament after each print, and you have to start by threading the filament, but the factory Creality models don’t have this function. However, if it doesn’t work even when sent from Orca, then first check the filament sensor. If there is filament in it, a small LED will light up blue. If there is a filament in it and it doesn’t light up, then either the sensor is not connected or it is bad. It could also be that the feeding extruder is not able to push the filament. There is a spring screw on the feeding extruder, it is worth winding it about halfway to make it clamp the filament with more force and prevent it from slipping. In addition to the previous slow boot process, if you use a USB hub, it can cause communication problems. For example, I tried 2 types, with one the camera works sometimes, sometimes not, with the other it doesn’t work at all. Now I’m going to try a third one, which has its own power supply.

Mine didn’t come with a filament sensor. Fluid doesn’t have the device option that mainsail has to get serial path. Should I have the sensor? Not all that I have seen have that under the splitter.

because it changes the USB device ID so the SW can’t find the path configured

serial:/dev/serial/by-path/platform-13500000.otg_new-usb-0:1.2.1:1.0

mine is configured to use

serial:/dev/serial/kcm

serial:/dev/serial/head

I never used a hub. That’s what mine were set at. Didn’t work. Why do some have the sensor and some don’t? Can’t find option to purchase one

creality kit has the sensor as it replaces the default sensor

coprint kit is generic

I noticed that they are constantly trying to improve their systems. The initial heads did not have a filament sensor. I got one that did. You have to ask Coprint, can you buy this separately, and can it be used with your system? I can’t imagine stable operation without it. Mainsail is not usable for me at all, only Fluid. And Fluid looks exactly the same to me as Mainsail does to others.

Le_zOU

With the USB hub, the problem is not the access path, but probably the USB power supply. For example, with me, the KCM works flawlessly with any USB hub, but the camera works with some of them at all, with others sometimes not. At least with me.

I also bought the KCM set from Coprint, and yet it has a filament sensor and a leveling sensor.

I just got a reply email from co print. They said after installing fw 1.2.3.63, I have to also update the config files. I must have bought the black sheep out of the batch. I’ve had it about 6 weeks. Not sure how they are doing the filament sensing.

wow, you’re a well of knowledge !!!

Thx, I’ve order a tiny USB hub so I can still use a USB key as the KCM is using the only USB port

USB plugged in, no reconfiguration necessary on FW 1.2.3.63

Yes, the Coprint wiki page still says that files need to be replaced, renamed, and cfgs need to be edited. Nevertheless, I followed the video below and it works. https://www.youtube.com/watch?v=Ewz_nrnl9GQ

works without changing anything with 1.2.3.63 firmware ![]()

Wow, this video is SO MUCH BETTER than the crappy co-print wiki and tutorial …

We should make a FAQ post for the KCM, with links and known issues/tips

I’ve experienced this in my life. Many devices only work from a USB hub if the hub receives + power. The Nebula camera may be like this. The KCM doesn’t need + power, it only needs communication, which is why it works with any hub.

Well, yes, Coprint could get itself together a little better. I know it’s a young company, but it could get rid of the old, outdated stuff because it just confuses customers.

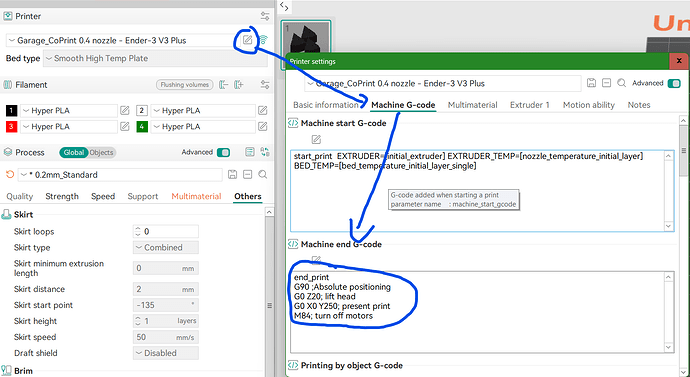

Other. I would be interested in how to print after printing and how to arrange the initial home position to the left, and much higher? I’m not very experienced in CFG editing. I haven’t dealt with such things before. I would only be interested in this because it’s inconvenient to remove the printer plate, because the print head stays very low.

you can add end print gcode in your slicer, here’s mine

end_print

G91 ; Set all axes to relative

G0 Z20; lift head 20mm

G90 ;Absolute positioning

G0 X0 Y250; present print, move bed forward to 25cm

M84; turn off motors

Note;

I place the M84 to be able to slide the hotbed freely, but it also releases the Z motor and since the chromahead is very heavy it may go down… so use carefully

(ignore the gcode in the screenshot it’s bad, the G0 Z20 moves head to 20mm above bed which will collide with print, my gcode above is fixed)

On a side note;

have you been able to handle end of filament correctly ?

What happens with mine;

filament end

print pauses had head moves to the front right,

old filament is cut and retracted

message displayed on LCD

I remove the top of the funnel with the small screw, pullout the bit of old filament

re attach the top of funnel

insert new filament in top of gantry extruder and push it until it triggers the filament sensor (blue LED ON)

extrude manually to feed the nozzle

Then the head moves automatically back to the print and leaves a blob on the print ;(

Thanks! I’ll look into this.

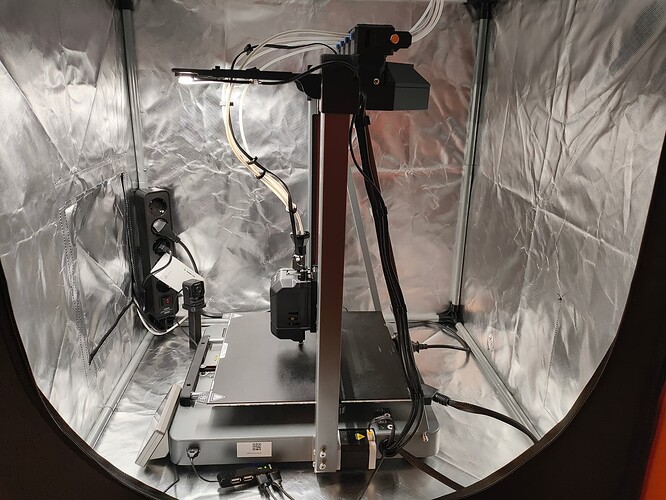

I haven’t had any experience with filament end-to-end switching, neither with Chromahead nor with the Creality head. I didn’t wait until it was completely gone, I replaced it first. I’ll try to see if the feeder extruder can push the cut piece through to the head extruder and if it can go all the way without getting stuck. In theory, you should flush it after changing filament, I think I saw the parameters for this somewhere, but I can’t find it now. Once with the original head, the filament got stuck because of the factory spool holder, and then the head got stuck on the print and melted a nice big hole in it. After that, it was able to continue, but the z-axis seemed to have moved a little closer to the print. This was one of those times. Anyway, today I was completely finished with everything and put it back in place.

This end g-code works, tested myself last night

end_print

G91 ; Set all axes to relative

G0 Z20; lift head 20mm

G90 ;Absolute positioning

G0 X0 Y250; present print

M84; turn off motors

Well, I found out that the older fw 1.2.3.30 works if you don’t have the filament sensor. Still have to set the serial paths up. Printed a single color perfect. Have tried color yet