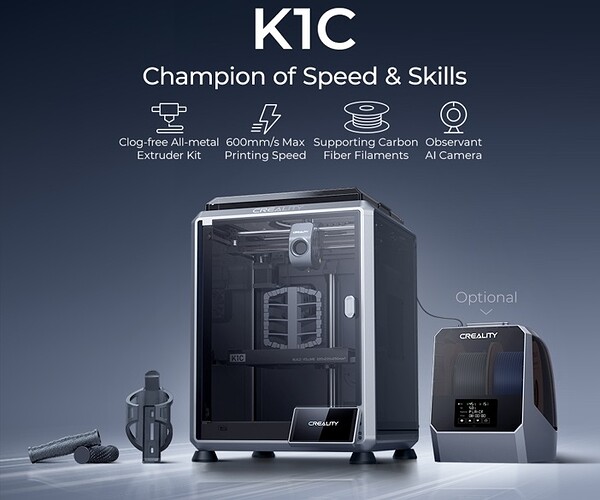

Creality has long been acclaimed as a leader in the 3D printer market. On January 25th, we will introduce our newest flagship model, the K1C 3D Printer Known as the “Champion of Speed and Skills,” this latest member of the Creality family is tailored to fulfill the needs of both enthusiasts and professionals who demand rapid printing capabilities, particularly with carbon fiber materials.

Building on the success of the esteemed Creality K1, the K1C is an enclosed Core XY FDM printer that can achieve speeds of up to 600 mm/s. Designed to compete with the industry’s top 3D printers, the Creality K1C sets a new standard with its all-metal hotend, upgraded motor system, and innovative build plate. The K1C’s capabilities extend beyond PLA; it is specifically optimized for the use of carbon fiber filament—the “C” in K1C denotes “carbon.” Furthermore, the K1C’s hotend can reach and maintain temperatures of up to 300 degrees Celsius, and its direct drive system is engineered to process carbon fiber filament with exceptional proficiency.

- Part 1: Creality K1C Printer Technical specifications and Innovations

- Part 2: Creality K1 Series Parameter Comparison

- Part 3: Creality K1C Printer Applications

- FAQs about Creality K1C 3D Printer

Part 1: Creality K1C 3D Printer Technical specifications and Innovations

1. Specifications Overview:

- Printing Technology: FDM

- Build Volume: 220220250mm

- Max Printing Speed: ≤600mm/s

- Extruder: All-metal direct drive

- Nozzle Temperature: ≤300℃

- Build Surface: PEI flexible build plate

- Leveling Mode: Hands-free auto leveling

- Supported Filaments: Wide range including PLA-CF, ABS, PLA, PETG, TPU, ASA, and carbon fiber composites like PA-CF, PET-CF

2. Key Features of the Creality K1C 3D Printer:

2.1 Champion of Speed and Skills

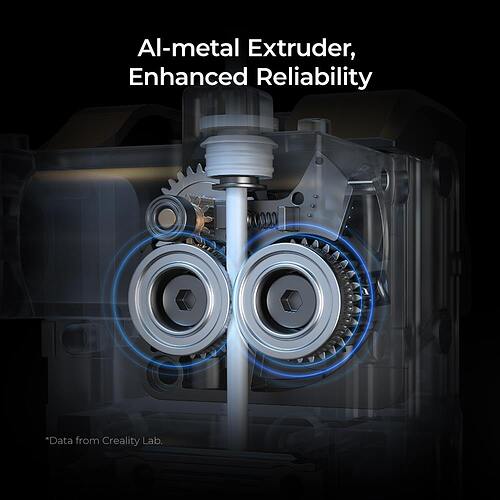

Reliable Extrusion

The K1C boasts an all-metal extruder kit, ensuring enhanced reliability during printing. With a bolster spring and ball plunger, the extruder maintains a strong grip on the filament, providing consistent and clog-free extrusion for over 1000 hours.

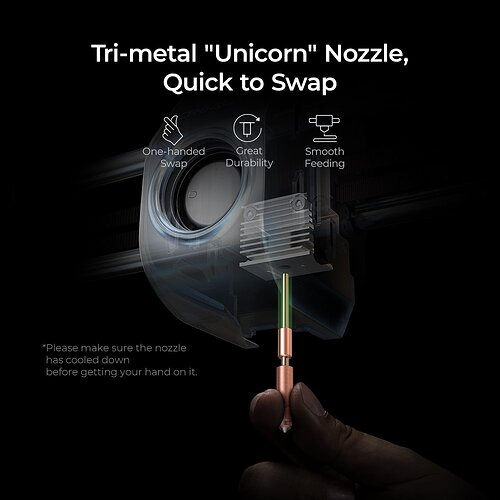

Quick-swap Tri-metal Nozzle

Featuring a tri-metal “Unicorn” nozzle with a steel-tipped copper build, integrated with a titanium alloy heatbreak, the K1C allows for easy one-handed swapping. This design prevents heat creep and ensures durability, providing smooth feeding and great durability.

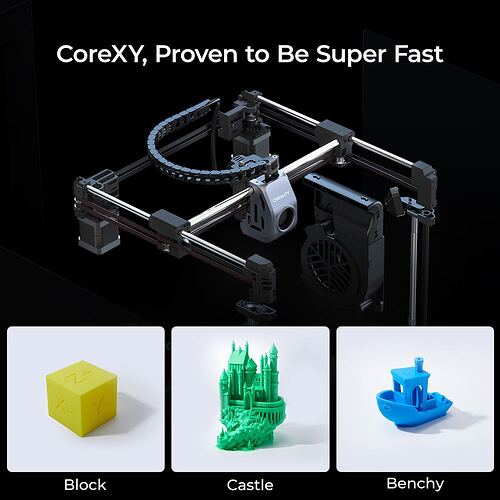

600mm/s Max Printing Speed

Powered by a CoreXY motion structure, the K1C achieves an astounding maximum printing speed of 600mm/s. This speed is complemented by a max acceleration of 20000mm/s², making it a true champion in the realm of 3D printing.

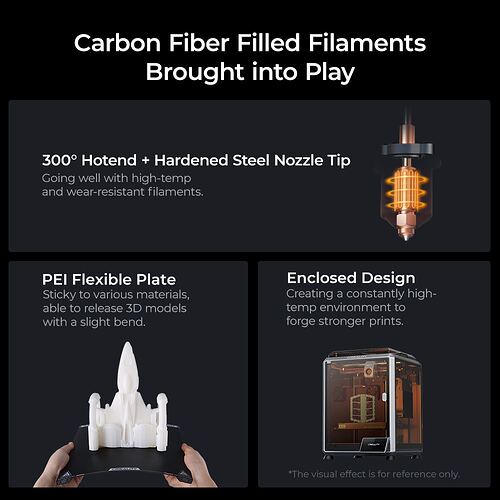

Supporting Carbon Fiber Filaments

Unleash your creativity with a 3D printer that supports a wide range of filaments. The K1C’s 300℃ hotend and hardened steel nozzle tip make it compatible with high-temperature and wear-resistant filaments, including carbon fiber variants.

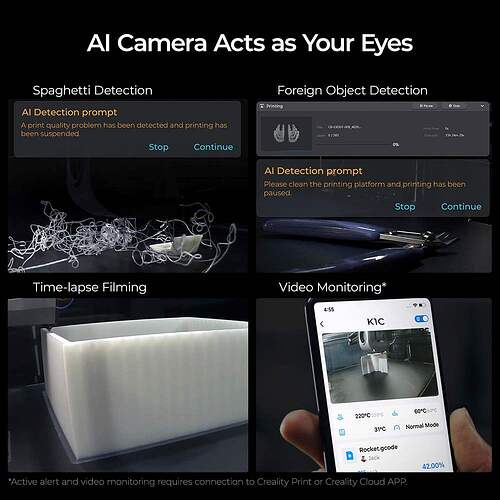

Intelligent AI Camera

Equipped with an AI camera, the K1C provides active error alerts, real-time monitoring, and time-lapse filming, ensuring a seamless and worry-free printing experience.

Wider Uses: Carbon Fiber Printing Reinvented

The K1C opens new possibilities with its compatibility with carbon fiber-filled filaments. Benefit from the mechanical strength and dimensional stability of materials like PET-CF and more, making it ideal for a variety of applications, from jigs and fixtures to prototypes.

2.2 Carefree & Smart Operations from Start to Finish

Auto Calibration with One Tap

Experience hassle-free operations with the K1C’s auto-calibration feature. With just one tap, the printer performs self-tests, auto-leveling, auto Z offset adjustment, and input shaping tests, eliminating the need for tedious manual leveling.

AI Camera Acts as Your Eyes

The built-in AI camera adds an extra layer of intelligence to your 3D printing experience. Detect errors, monitor progress, and enjoy the convenience of remote monitoring through Creality Print or Creality Cloud APP.

2.3 Champion of Speed, Indeed

CoreXY Motion Structure

Inheriting the lightweight and agile CoreXY motion structure, the K1C promises not only speed but also high print quality. With a silent mode option, the printer operates at a noise level as low as 45dB, ensuring a quiet printing environment.

2.4 Contemporary Style and Robust Build

Solid Frame Using Die Cast Parts

The frame adopts bigger parts made by integrated die casting.With fewer seams, it looks neat and becomes utterly sturdy.

Glass Sides and Transparent Lid

The glass sides and the acrylic lid form up a stylish thermal enclosure,and they are transparent to reveal what’s going on inside.

Active Carbon Filter for Clean Air

The K1C utilizes an active carbon filter to purify compounds and particles, offering a pleasant and clean printing environment.

Details, All for the Best

The K1C incorporates various features for enhanced user experience, including pre-installed damping pads, a reliable damper hinge, an anti-shatter film, a reinforced cable chain, and a silicone wiping strip, among others.

Make Creality K1C Even More Powerful

Enhance the capabilities of your K1C with quality optional accessories, including Creality Hyper Filaments, Creality Space Pi Filament Dryer, and a Coarsely Textured PEI Plate for better adhesion.

2.5 Creality OS & Superb Software

Open-source Creality OS

Based on Klipper, Creality OS empowers users with advanced functions such as linear advance and input shaping. Enjoy the freedom to customize or join the open-source community for more exploration.

Creality Print: More Than Just a Slicer

Creality Print features smart cooling, optimal retraction, slim tree supports, and integrates a readily accessible 3D model library, offering a seamless 3D printing experience.

Creality Cloud: Engaging Online Community

Join a diverse and interesting 3D printing community with Creality Cloud. Access a 3D model library, cloud printing capabilities, and interact with other enthusiasts.

24/7 Smart Customer Service & 1-Year Warranty

Experience peace of mind with Creality’s 24/7 smart customer service and a 1-year warranty, ensuring comprehensive support for your K1C 3D printer.

Part 2: Creality K1 Series Parameter Comparison

Next, we will comprehensively introduce K1 series parameter comparison to help readers better understand K1C Printer.

| Model | K1 | K1 Max | K1C |

|---|---|---|---|

| KV |  |

|

|

| Release Date | 2023.4 | 2023.4 | 2024.1 |

| Printing Technology | FDM | FDM | FDM |

| Build Volume (mm) | 220220250 | 300300300 | 220220250mm |

| Product Dimensions (mm) | 355355480 | 435462526 | 355355482mm |

| Package Dimensions (mm) | 415415550 | 508508608 | 441441578mm |

| Net Weight(kg) | 12.5kg | 18kg | 12.4kg |

| Gross Weight (kg) | 16kg | 23kg | 16kg |

| Supported Filaments | PLA, Hyper PLA, PETG, ABS,TPU,ABS,PA | PLA,Hyper PLA,PETG,ABS,TPU,ABS,PA | PLA-CF,PA-CF,PET-CF, ABS,PLA,PETG,PET,TPU,PA,ABS,ASA,PC |

| Printing Accuracy | 100±0.1mm | 100mm±0.1 | 100mm±0.1 |

| Layer Height | 0.1-0.35mm | 0.1-0.35mm | 0.1-0.35mm |

| Filament Diameter | 1.75mm | 1.75mm | 1.75mm |

| Build Surface | Flexible build plate | Flexible build plate | PEI flexible build plate with silicone wiping strip |

| Heatbed Temperature | 100℃ | 100℃ | ≤100℃ |

| Nozzle Temperature | 300℃ | 300℃ | ≤300℃ |

| Extruder Count | 1 | 1 | 1 |

| Nozzle Diameter | 0.4mm | 0.4mm | 0.4mm |

| Printing Speed | 300mm/s | 300mm/s | 300mm/s |

| Max. Printing Speed | ≤600mm/s≤20000mm/s² | ≤600mm/s≤20000mm/s² | ≤600mm/s≤20000mm/s² |

| Display Screen | 4.3" color touch screen | 4.3" color touch screen | 4.3" color touch screen |

| UI Languages | 10 Languages English, Spanish, German, French, Russian, Portuguese, Italian, Turkish, Japanese, Chinese | 10 Languages English, Spanish, German, French, Russian, Portuguese, Italian, Turkish, Japanese, Chinese | 10 Languages English, Spanish, German, French, Russian, Portuguese, Italian, Turkish, Japanese, Chinese |

| Rated Input Voltage | 100-120V~/200-240V~ | 100-240V~ | 100-240V~, 50/60Hz |

| Output Voltage of Power Adapter | 24V | 24V | 24V |

| Rated Power | 350W | 1000W | 350W |

| Silent Mainboard | Yes | Yes | Yes |

| Extruder | Dual-gear direct drive extruder | Dual-gear direct drive extruder | All-metal direct drive extruder |

| Dual Z-axis | 3 Z-axis | 3 Z-axis | 3 Z-axis |

| Leveling Mode | Hands-free auto leveling | Dual hands-free auto leveling | Hands-free auto leveling |

| Air Purifier | x | x | √ |

| Input Shaping | √ | √ | √ |

| Sleep Mode | X | X | √ |

| Power Loss Recovery | √ | √ | √ |

| Filament Runout Sensor | √ | √ | √ |

| Remote Printing | √ | √ | √ |

| Enclosure | √ | √ | √ |

| Remark | AI Camera(Optional) | AI Camera, AI LiDAR | AI Camera |

| File Transfer | USB drive, WiFi | USB drive, WiFi | USB drive, WiFi |

| Printable File Format | G-Code | G-Code | G-Code |

| File Formats for Slicing | STL, OBJ, AMF | STL, OBJ, AMF | STL, OBJ, 3MF |

| Slicing Software | Creality Print; Cura, Simplify3D, PrusaSlicer | Creality Print; Cura, Simplify3D, PrusaSlicer | Creality Print, Cura 5.0 and later version |

Part 3: Creality K1C Printer Applications

| Robot Model Printing Scenarios (By making rational use of these materials, it is possible to manufacture robot models with superior performance, long lifespan, and low cost. | Description |

|---|---|

| PLA | It is the most common 3D printing material, low cost, easy to print, and can be used to print the exterior shell of robots and non-critical structural parts. |

| PLA-CF | This material has higher stiffness and strength and can be used to print robot parts that need to withstand greater forces, such as the robot’s main support structure. |

| PETG | This material is wear-resistant with high impact strength and can be used to print robot gears and other moving parts. |

| ABS | This material is strong, impact-resistant, and heat-resistant, suitable for printing robot parts that must withstand high-temperature environments. |

| ASA | This material has good UV resistance and weatherability, suitable for printing robot parts used outdoors. |

| TPU | This material is flexible and can be used to print robot tires and other parts that require flexibility. |

| PA | This material is wear-resistant and impact-resistant, suitable for printing robot gears and other high-strength parts. |

| PC | This material has very high strength and heat resistance, suitable for printing robot parts that must withstand extremely high loads or temperatures. |

| PA-CF | This material has extremely high stiffness and strength, suitable for printing the robot’s main support structure and parts that bear high loads. |

| 3D Printing Architectural Model Scenarios | |

| PLA | PLA is a mainstream 3D printing material because it is easy to print, has high precision, and offers a variety of colors. For instance, PLA can be used to print the main body of architectural models, such as walls and roofs. |

| PLA-CF | PLA-CF is a mixture of PLA and carbon fibers, offering higher strength and stiffness, suitable for printing parts that require higher strength, such as support columns of buildings. |

| PETG | PETG has good toughness and weather resistance, suitable for printing parts that need to withstand pressure, such as bridges and support structures. |

| ABS | ABS has high strength and good heat resistance, suitable for printing parts that need to withstand high temperatures, such as chimneys or ovens in models. |

| ASA | ASA has high weather resistance and can be used to print parts that will be exposed to sunlight for extended periods, such as the exterior walls and roofs of models. |

| TPU | TPU is highly elastic and can be used to print flexible parts, such as model doors, window curtains, or small decorative items. |

| PA | PA has high wear resistance and chemical corrosion resistance, suitable for printing parts that require wear resistance, such as floors or steps. |

| PC | PC has high transparency and can be used to print parts that require a transparent effect, such as windows or glass curtain walls. |

| PA-CF | PA-CF is a mixture of PA and carbon fibers, offering higher strength and stiffness, suitable for printing parts that need to withstand greater pressure, such as bridges or load-bearing walls of buildings. |

| Innovative Automotive Design and Manufacturing Field (3D printing technology and a variety of printing materials have played a significant role. For example, designing a new car model, each part may need to be printed with different materials to maximize the effect and performance.) | |

| PLA | This material produces objects with high hardness but also greater brittleness. Therefore, it can be used to print the car’s exterior shell or other parts that do not need to withstand much pressure. |

| PETG | This material has good toughness and heat resistance, suitable for printing parts of a car’s engine or internal structure. |

| ABS | This material also has good heat resistance and impact resistance, and can be used to print the car’s chassis or tires. |

| PLA-CF | This material has higher strength and stiffness, suitable for printing the car’s protective bars or bumpers. |

| ASA | This material has excellent weatherability and UV resistance, suitable for printing the car’s external trim pieces. |

| TPU | This material has good wear resistance and toughness, suitable for printing the car’s seats or interior trim. |

| PA and PA-CF | These two materials have excellent mechanical properties and heat resistance, suitable for printing car engine parts or transmission systems. |

| PC | This material has high impact resistance and transparency, suitable for printing car windows or light covers. |

| Furniture Design Scenarios | |

| PLA | This is the most commonly used material in 3D printing, made from plant starch, with biodegradable properties. In furniture design, PLA can be used to print decorative and non-structural parts, such as lampshades, vases, or small decorative objects. |

| PETG | PETG is a durable plastic with good impact strength and flexibility. These properties make it an ideal choice for printing furniture parts that need to withstand pressure or impact, such as chair legs or tabletops. |

| ABS | ABS is a plastic with high strength and wear resistance, suitable for printing parts that need to withstand high pressure and high temperatures, such as the seat of a chair or the top of a table. |

| PLA-CF | PLA-CF is a modified form of polylactic acid, with added carbon fibers to increase its strength and stiffness. This material can be used to print parts that require higher strength and stiffness, such as the frame of a table or chair. |

| ASA | ASA is a plastic with excellent weather resistance and UV resistance, suitable for printing furniture that will be used outdoors, such as patio furniture or garden furniture. |

| TPU | TPU is a material with excellent flexibility, suitable for printing parts that require some elasticity and softness, such as chair cushions or sofa pads. |

| PA | PA is a wear-resistant and impact-resistant material, suitable for printing parts that need to withstand high loads, such as the base of a bed or the supports of a table. |

| PC | PC is a very strong and transparent plastic, suitable for printing parts that require transparency or translucency, such as glass tabletops or transparent ornaments. |

| PA-CF | PA-CF is a modified form of nylon, with added carbon fibers to enhance its strength and stiffness. This material can be used to print parts that require higher strength and stiffness, such as table legs or the frame of a chair. |

| Automotive Manufacturing Scenarios | |

| PLA | PLA is a bio-based, biodegradable material with good printing performance and sufficient strength. In automotive manufacturing, PLA can be used to print interior decorative pieces, such as decorative panels on the inside of car doors, small storage boxes in the car, cup holders, etc. |

| PETG | PETG is a material with high strength, impact resistance, and good flexibility. In automotive manufacturing, PETG can be used to print some exterior components of the car body, such as bumpers, spoilers, etc. |

| ABS | ABS is a material with high strength and heat resistance, suitable for printing parts that need to withstand higher mechanical and thermal loads. In automotive manufacturing, ABS can be used to print engine covers, wheel rims, brake system components, etc. |

| PLA-CF | PLA-CF has high rigidity, strength, and lower weight, suitable for printing parts that need to be lightweight yet maintain high strength. In automotive manufacturing, PLA-CF can be used to print structural body parts, seat frames, etc. |

| ASA | ASA has good weather resistance and high wear resistance, suitable for printing parts that need to be exposed to outdoor and harsh environments for long periods. In automotive manufacturing, ASA can be used to print car roofs, window frames, etc. |

| TPU | TPU has good elasticity and wear resistance, suitable for printing parts that require a certain degree of elasticity. In automotive manufacturing, TPU can be used to print car seat cushions, seat coverings, suspension system components, etc. |

| PA and PA-CF | PA and PA-CF have high strength, high wear resistance, and good chemical resistance, suitable for printing parts that need to withstand high mechanical and chemical loads. In automotive manufacturing, PA and PA-CF can be used to print gears, bearings, connecting rods, crankshafts, etc. |

| PC | PC has high impact strength, high transparency, and good heat resistance, suitable for printing parts that need to be transparent and need to withstand impact. In automotive manufacturing, PC can be used to print car windows, light covers, etc. |

| Bicycle Scenarios | |

| Define handles: | You can use 3D printing technology to create bicycle handles that perfectly fit your hand size, increasing riding comfort. |

| Frame plugins: | If you need to add additional equipment to your bicycle, such as lights or GPS, 3D printing can help you create perfectly fitting frame plugins. |

| Custom pedals: | Like handles, you can also use 3D printing technology to create pedals that perfectly fit your foot size. |

| Chain guards: | Use 3D printing technology to create unique chain guards, which not only protect the chain but also add to the bicycle’s aesthetic appeal. |

| Custom saddles: | Through 3D printing, you can create a bicycle saddle that stands out, tailored to your body type and riding habits. |

| Water bottle holders: | Through 3D printing, you can create uniquely designed water bottle holders for easy access while riding. |

| Custom tires: | If you want tires with special patterns, you can use 3D printing technology to print tires that meet your personal needs. |

| Custom fenders: | You can print uniquely designed fenders that are both practical and personalized. |

| Chair Backs | |

| Door Handles | |

| Car Trunk Latches | |

| Car Support Brackets | |

| Door Bumpers | |

| Drones, Cars, Boats, Tool Boxes | |

| Kitchen scene, bathroom scene, bedroom scene, living room, workspace | |

| Office desk scene | |

| Electric skateboard (bracket, wheels, control box, wheels with motors, control box), helmet, protective gear, wrist guards |

FAQs about Creality K1C 3D Printer

1. Is the Creality K1C already on sale?

It will be available for pre-order from January 25th.

2. What is the price of the Creality K1C?

The price for the K1C is $559 (please note that the specific price may fluctuate based on festivals and events).

3. What are the discounts for the K1C pre-sale event?

- Customers can enjoy an extra 5% off pre-order offer when you pre-order the K1C 3D printer at the Creality Official Store. Pre-order offer is valid from Jan. 24 to Feb. 6.

- For customers who pre-order the K1C during the pre-order period, one lucky winner will be randomly selected to receive the K1C for free and get a full refund. Winner will be announced after pre-order offer ends.

- ustomers may claim a 1-year free Creality Cloud Premium after receiving the K1C 3D printer.

4. Why is it called K1C, and what makes it a high-speed 3D printer for carbon fiber materials?

The “C” signifies its support for carbon fiber materials. Features like a powder metallurgy lever, lateral spring support, and built-in filament detection make it reliable. The integrated nozzle system ensures smooth filament flow for quality carbon fiber prints.

5. What are the key speed and quality features of the Creality K1C 3D Printer?

The CoreXY motion structure enables high-speed printing with excellent precision. Dual cooling ensures quick and quiet printing, and mechanical optimizations, like a 20-tooth gear and improved fan balancing, contribute to enhanced print quality. The user-friendly design requires no assembly or calibration.

6. What additional support and convenience features does the Creality K1C 3D Printer offer?

The K1C provides an AI camera for fault detection, foreign object detection, and remote monitoring. It supports side-loading filament and offers software-assisted operations through the open-source Creality OS. Users can skip printing a defective model during batch printing with Creality Print. The machine includes damping pads, reinforced cable chains, a silicone wiping strip, and additional accessories for enhanced reliability and convenience.

7. What are the notable optimizations in the Creality K1C 3D Printer, and how does it enhance material diversity?

The K1C introduces upgrades like a built-in camera, carbon filter for air purification, and support for various materials, including engineering and standard filaments. These enhancements come at no additional cost, ensuring a versatile and high-performance 3D printing experience.

8. How does the Creality K1C balance speed and quality in its printing process?

The K1C maintains high-speed printing with its CoreXY motion structure. Upgrades in the extruder, hotend, synchronous belt (20 teeth), and cable chains contribute to speed and quality improvements. This ensures a consistent and reliable printing experience.

9. What user-friendly features make the Creality K1C an easy-to-use 3D printer?

The K1C simplifies the 3D printing process with its out-of-the-box functionality, automatic features such as leveling, height adjustment, and flow optimization. The nozzle assembly is easily replaceable for user convenience, making it an ideal choice for both beginners and experienced users.

Conclusion

The Creality K1C is not just a 3D printer,it is a comprehensive solution for demanding printing tasks, offering a blend of speed, durability, and advanced features. With the backup of a 1-year warranty, 24/7 customer service, and a rich hardware and software ecosystem, the K1C is poised to be a game-changer in the world of 3D printing. Whether you’re producing jigs & fixtures, prototypes, product shells, or toys, the Creality K1C 3D Printer stands ready to deliver high-quality prints at remarkable speeds.

People also read: