Brand new, have had less than a week and can’t get this thing to print correctly.

I was able to print the boat that came with the Ender usb, and one other small print. Everything else I’ve tried does not work.

I’ve cleaned the plate and made sure the nozzle wasn’t clogged but i keep having issues.

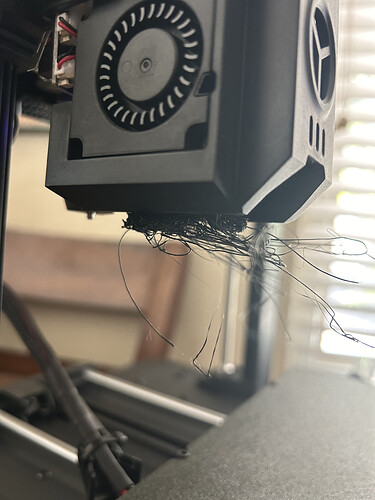

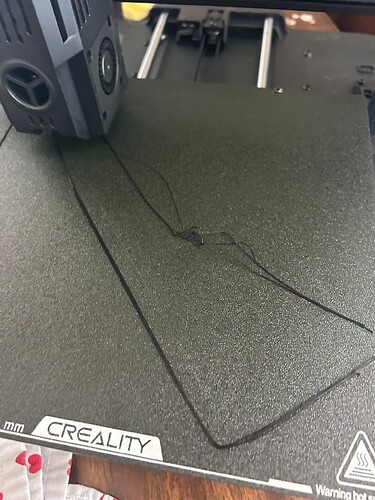

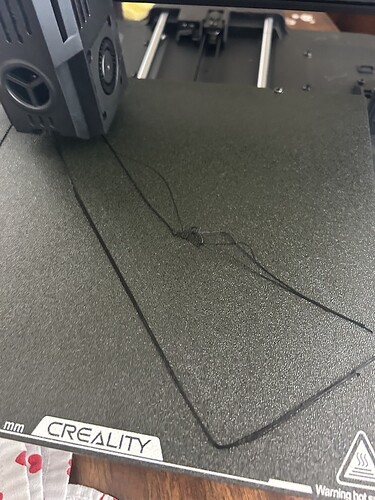

I either get filament spider webbing all around the nozzle or it’ll start the first layer, look great and then lifts up and is dragged across the bed. (see images)

I dont know what to do and I’m starting to lose my patience.

I’m trying to print this :

Filament spool

I’ve used stander default settings. I’ve used the settings recommended in the description. I’ve sliced it on Creality Print and on Cura and keep getting the same issue.

Please help

1 Like

Z offset, after calibrating you will also need to move the print head down by another 0.05-0.1mm to get a good squish to the extruded material. Personally I print a 3 wide skirt (build plate adhesion type = skirt) and use that to get the Z offset correct. Takes a little practice but once you’ve nailed it no more spider webs. I use this method on all 4 of my printers and it works almost every time.

2 Likes

It’s hard to tell from the pictures, need to see the good first layer you said you had but looks like you maybe a bit high on your z and it’s pulling back away, try adjusting your z add a brim so you can see it before it goes into your print.

The auto z can work great but sometimes needs a bit more adjustment I find depending on filament it’s +/-.5

1 Like

Both writing the same thing at the same time. Great minds or something like that

Great minds think alike or idiots rarely differ, you choose

1 Like

Knowing myself I would say the latter haha

It’s something my dad would say. Anyway Z offset, it took me almost a year to get it right on an Ender 5 plus, never had to worry on my Snapmaker that just works. Essential skill to master, even though we have autoleveling it needs a little tuning. Just wish my resin printer was that easy. Patience and practice is what is needed or take Creality to court for selling you something that isn’t plug’n’play. Material choice is also a thing, PLA should be simple if the filament isn’t wet, get a dryer. PETG a bit of pain, I often get stringing but not enough to ruin a print. TPU less stringy but prints fine. If you haven’t bought a dryer get one, you’ll thank me (unless you live in a desert)

Thank you, i’ll try this and let you know

When you adjust the Z you should see the extruded bead flatten onto the bed. If you flatten it too much it will pucker up and lift, just back off on the Z. You shouldn’t need a glue layer (Prittstick) but I sometimes do on one of my build plates, that would be when I am printing 20 odd parts at a time.

Is it best to adjust while the unit is not printing or while it is printing?

While it is printing hence why I run a skirt, I adjust it as it is running the skirt before it gets to first print layer. Does mean that you need to be at the printer rather than remotely. Once dialled in you can remote print.

Ok cool.

I’ll give it a shot soon as I get home.

What’s the typical distance you’ve seen for pla on this machine?

Mine is 2.51 but with another filament it’s 2.53 you can’t take someone else’s it doesn’t work that way, it’s small amounts based on circumstances of your machine and its level

Thanks. I’ll let you know how it goes

so

thought i didn’t have it…then thought i did…then , didn’t.

I"m not sure wtf is going on. i’ve tried all the z offset adjust ments from too low to too high and nothing works. i’ve cleaned the bed to make sure that wasn’t the problem. Nothing prints.

the skirt would print perfectly but once it went over to the model, it just resumed its issues again.

I even completely reset the and went to re print the original boat on the original settings when I did it the first time…this time…looked great, then after 5% done , it went to shit again.

I’m not sure whats going on.

Literally the only thing different between the very first two successful prints and now is I was using the sample filament provided with the unit. and now, I’m using their brand, Creality pla 175…but i accounted for that in creality print and cura slicing.

Glue stick might work. Personally not a fan of Creality PEI, rather use Fysetc. Either way a bit of glue stick can work Guessing by username you aren’t in the UK, if you were the Tesco Office glue stick is great.

It’s a brand of build plate

1 Like

Amazon shop for their stuff I think I saw somewhere that they are selling FDM machines too, not that I need any more at present.

1 Like

Yes she has 2 horses I have 3 printers and it’s 5 too many