I’ve been battling extruder problems all week. Every time I fix a problem it’s something else. Like okay, fine… but I got the process down to a science and I was really hoping after fixing the ptfe tubing and unclogging and cleaning the nozzle and stream lining the filament and got it all back and printing for like the 15th time that when the job finished I was in the clear. Great print as usual. No cfs problems as the filament retracted properly. But I’ll be damned if I didn’t get an error saying there is a filament read error or something. I knew what it was. I took the assembly apart again and there is filament in the stem. The cutter cut the filament. I’m losing my mind. I know I can unclog it and put it back together again and recalibrate and get another print done but what’s going on here that I’m missing? I’m not putting this thing back together again unless I feel like I’m actually fixing something. Help please?

I’m having sort of similar issues. Most errors for the extruder tends to be ghosts as there is nothing in the way or blocking anything. I have also got the extruder and nozzle removal down to a science. This is all right oit of the box with these issues. One thing I have noticed for my situation is I have to start the print from the screen on the printer AND it has to run the 2 print tests on the two sides of the bed in order to keep printing. Now most of my issues are more coming from the CFS when its changing filaments. I hit retry and it starts working for a few more layers then that same error comes up again. Hit retry and rinse repeat until the print is done. I wouldn’t think for $2k (printer and 2 CFS units) I would be having all the trouble out of the box like I have had but here we are. LOL Good Luck and I hope you find a fix for your issue as well. I’m sorry I couldnt help, but figured I would let you know you’re not alone.

I was having strange extruder errors and Buffer errors too. Then, while watching the blue LED light on the buffer, I moved the buffer connection cable on the top of the buffer, and the LED would flicker. I snapped apart the buffer, and took out the board. I found the connector had some cold/weak solder joints… reflowed them, and it has not failed since, nor have I had any extruder errors. I think the buffer unit is sending a false error signal that there is a filament jam, and then the extruder stops. Hope it helps a bit.

I’m unsure if this is relevant, but I had similar issues. The last issue indicated that I had a filament loaded from the external holder and would not use the CFS. I disassembled the extruder and removed the screws that held the extruder motor in place. I found that the little ribbon cable to the filament sensor was pinched between the motor mounting and the frame. I rerouted the cable and have not had the problem since. I plan on replacing that cable when support gets back to work!

I noticed mine flickers as well. I hadn’t thought to open it up but I’ll add that to the list. I’m going to order a soldering kit so maybe that will be a project for this weekend. I keep rebuilding this thing 5-10 times a night fixing a problem and getting new ones. It doesn’t seem to be just one specific problem at this point but I think I have that buffer problem as well so hopefully that will help. I appreciate it.

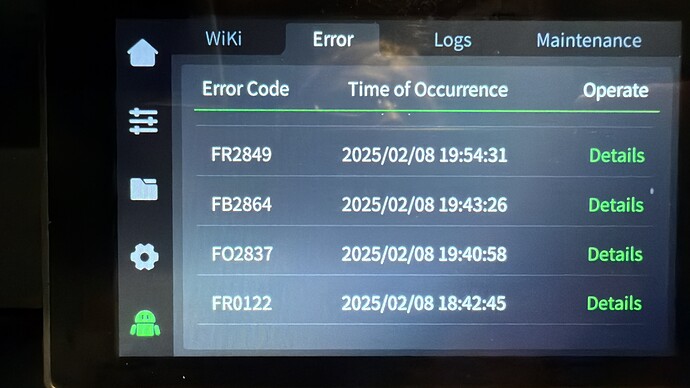

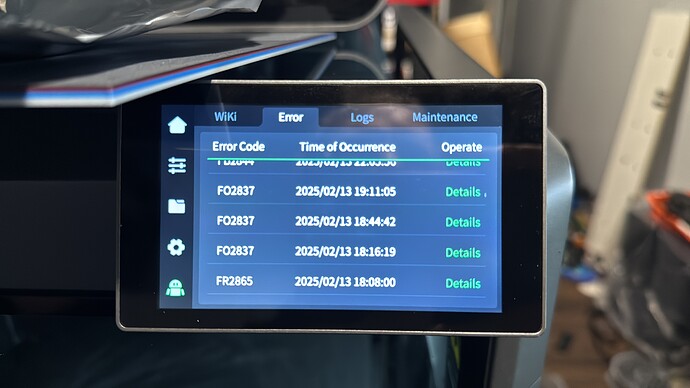

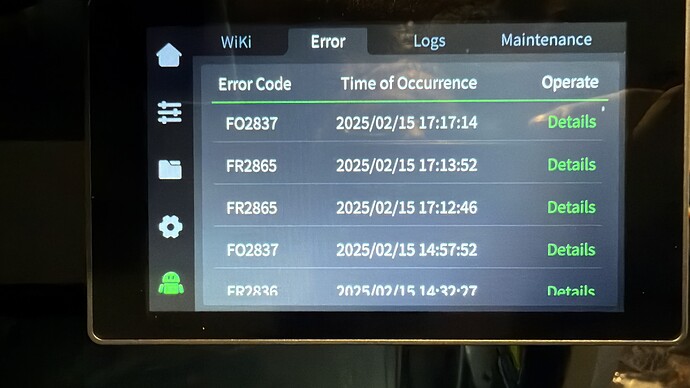

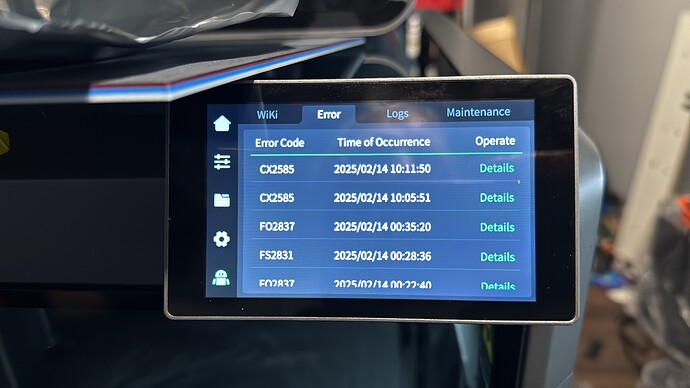

“Down to a science” cracks me up. I likened it to nascar pit crews changing a tire. I can do it in under 5 minutes easy now. I think a lot of my problems are ghosts but then sometimes they’re not. I found a post somewhere about the tiniest obstruction can cause a problem with the extruders sensor so the next time it gave me an error I took it apart and I did manage to find a tiny piece of red filament. It was the size of a hair. I had to use the zoom on my phone and take a picture to even get a decent look at it. I removed it and got the printer working for another 12 hours. It failed at 70% through the next 12hr print so I threw in the towel for a day. I’m sad this seems to be par for the course because when it prints it’s awesome. Plus my fingers hurt at this point. I checked the error logs last night and I’m at like 50 errors since I factory reset the printer Monday so that’s 50 times I’ve taken apart the extruder assembly in 72 hours.

Me too. Now I can disassemble the extruder with my eyes closed.

I just discovered something today. The extruder motor stays on when idle, even overnight. and the extruder gears are hot. Hot enough that I can barely touch it. I’m guessing that the heat from the extruder motor propagate to the filament, causing softening to the filament, and thus jam in the heatbreak. I tried to add M18 E to turn off the extruder motor in the filament end gcode, but that is causing ‘Print Not Finished’ error message, and all motor (XYZE) turned off. Meaning in multi material situation, this is not suitable. The only possible thing is to add the gcode in the Post-Processing scripts, I guess. But I don’t know how to do it.

Hi how are you all fixing your extruder?

Please do me a solid. Take some of the filament you have cut off and spin the fan on the right of the extruder inline with the extruder motor. I suspect the fan was jammed by the extruder filament sensor cable and has cooked your extruder motors slowly and now the only fix is is to replace it.

A solid what ?

In the loo

Just checked. Extruder fan is working. Now I put white marks on each fan so I can easily see whether its running or not. And on the extruder gear as well.

Now I get: XS2353 System error, try restarting. Just when my print was 80% finished.

I hate this machine. I have no confidence at all when printing with this machine. Its just like playing russian roulette.

I’ve experienced this too, with Creality Hyper PETG last week. Had tons of errors and faults related to extrusion and filament. Had to cut the filament bulge out of the extruder. Was racking my brain trying to understand how the filament could bulge there; hot motor makes sense. They’re not reducing current when idle?

This week battling 1st and 2nd-layer issues, Z offset, and taco-shaped bed. PETG does not like to print on this thing at all.

There may be a (hot motor) answer in “rooting” the device and changing the config somehow to turn off all motors after a period of inactivity. But I don’t know what that is yet (and the notice says rooting voids the warranty.)

PETG not sticking to the bed? that is strange. I use Sunlu PETG, and old CCTREE PETG, no problem at all. Bed temp 70c, chamber temp 45c, nozzle 250c. I find the textured PEI plate adhesion is very good. Even for ABS. No glue at all.

And what do you mean by “filament bulge out of the extruder” ?

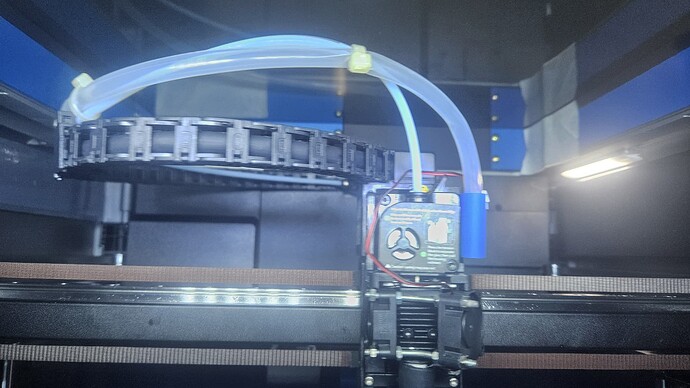

Anyway, I tried adding cooling to the extruder, using 20 lpm aquarium aerator pump and silicone tubing. I have not done any extensive print test yet, but on 40 minute print, it seems promising.

If you lift off the hot-end cover, then remove the extruder cover, the pinch rollers are visible. What we mean is the little bit of filament visible above the pinch rollers - it bulges, wider than 1.75mm, such that it then cannot be retracted. Only solution is to remove the rollers and cut out the bulged section.

Edit: since reverting to .57 firmware, trying CrealityPrint 5 (no help), then moving everything back to latest and CP6, the extruder seems to be behaving again. VERY finnicky. Currently trying to manually level the inverse-taco-shaped bed.

Unfortunately, you need to “feel” this printer due to issues as described in my post: My honest opinion about K2 Plus after two month

Many other problems is consequences.

For example, i think, early or late, all 100% of PTFE spring washers inside the extruder shell will be broken. If your washer is half-broken, PTFE is still on place, but not vertically. And your filament have resistant force, so you have errors.

Only one way for now - change the extruder shell for new, its cheap.

I took out extended warranty with my Printer and as a result of the issues over Chinese new year had to use extended warranty. Allstate approved the repair but could not get someone to come out and service it for 2 weeks. So they decided to pay out on it.

Good when I get to keep it and get refund on the whole money paid

If you lift off the hot-end cover, then remove the extruder cover, the pinch rollers are visible. What we mean is the little bit of filament visible above the pinch rollers - it bulges, wider than 1.75mm, such that it then cannot be retracted.

Yep. it happend to me too. Just like printing with soft material. So my current solution is to cool the extruder gear by blowing cold air from outside. So far so good. At leat for me.