I am relatively new to 3d printing and my Ender 3 v3 SE is not functioning properly. I tried to remove the nozzle to clean it but it would not move. I do not know if I’m doing anything wrong. Please help if you can.

Was funktioniert nicht richtig? Eine genaue Beschreibung wäre hilfreich.

Auf Seite 18 im Handbuch wird der Nozzle tausch erklärt, denke daran das sie dazu aufgeheizt sein muss.

I have seen many tutorials online about it and I followed every step in them. The nozzle seems to be completely stuck and doesn’t move. I have heated it properly (at least I think so) but it will not rotate. I want to remove the nozzle to clean it. Moreover the tools I have are limited, but according to the tutorials the tools I possess are enough. If needed I will send pictures.

I might be unscrewing it the wrong direction. Is it clockwise or anti-clockwise?

Righty tightie, lefty loosy. You unscrew almost any common part CCW.

I had to put mine in a vice and lean on a 6mm socket wrench to undo it, luckily there are only short leads on the V3SE hotend, unlike my Ender 5 plus, that is like wrestling with a snake.

Thanks a lot for helping. I will try tomorrow when I’m free. I have a question, is it the method for most printers or just Ender 3 printers?

Should be able to get a nozzle out without a full strip down, I just go overboard as I have the vice and M6 tapping wrench in my shed. Most printers use those nozzles or similar ones so I guess the answer is yes for most printers. Unicorn and Flowtech nozzles should be easier to remove as you shouldn’t be able to get molten material onto the threads.

If I get any more printers I will remember this. Thanks a lot!

The unicorn nozzle was one feature that I liked about the K1C, I figured that would be more bulletproof than the multiple pieces.

The Microswiss Flowtech is similar in construction, I have it fitted to my V3SE, will fit it to my V3KE if that suffers blob of death.

Not sure what you are pre heating to, but I pre heat mine to 240c and then remove the nozzle with this

Slice Engineering Nozzle Torque Wrench

Make sure you hold the heat block with pliers

I tried everything and it’s still stuck. Please help

You have to hold the ceramic heater end with pliers and use a 6mm socket or quality wrench to break the nozzle free. You can not expect to rely on the tools that were included with the printer, they are of very poor quality. If your nozzle is seized like mine was your going to need some uprated tools to get the job done.

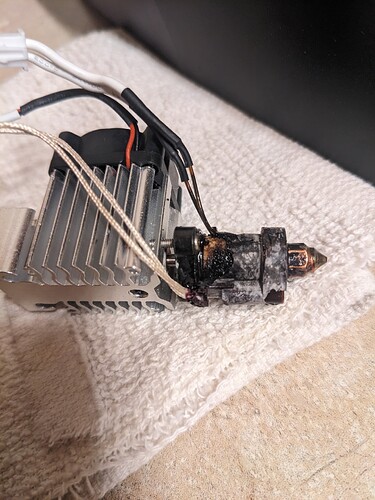

In addition, do not twist the ceramic heater unit as you will twist and possibly break the tiny screws holding it to the heat sink. Here is a picture of mine, it’s pretty roached.

I bring my Ender 3 hot end up to temp and then replace the nozzle without major disassembly.

Finally we removed the nozzle, because a mechanic came over to fix the bathroom lights as just today the entire celing fell off (unrelated but still important) and he agreed to remove the nozzle even though he doesn’t know anything about 3D printing, All it took was 5 minutes, and a LOT of force. It took so much force that this is how the nozzle looks after.

It took tools that were not meant for 3D printers but we removed it. Does it have to be that tight? As tight as it was when I got the printer?

If you first heat it up to operating temp and then remove it it shouldn’t be that tight. I’ve used the socket and wrench include in the Creality tool kit without any problems.

Got to be tight so there is no filament leak between the nozzle and heat break, though not quite as tight as that.

Right off the top I can see that the beginning of the threads are stripped/chewed up. Your hot end nozzle is probably got roached threads and if you install a new nozzle you’re likely to encounter the same situation.

Check the threads in the hot end and run a tap through them to clean them up if needed or replace if required. I might also use a little anti seize on the threads of the nozzle, but I personally have not done this myself as of yet. I am of firm belief that the compromised threads here are the root causation of your seized nozzle.