Ohms are a simple function/test with a meter. Even a $4 Harbor Freight meter will be fine for ohms and volt purposes.

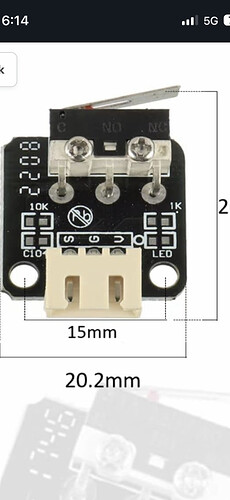

Your switch will be similar to the one in picture. If you look at the switch itself you will see it has 3 poles.

One marked C, for common, one marked NO for normally open and one marked NC for normally closed.

You want to unplug cable, hook ohm meter to the C and NO poles.

With ohm meter set to ohms (usually looks like sideways Wi-Fi signal graphic) hook to the C and NO poles of switch.

When not activated (not touching X home position) you will see no change on meter.

If you push the button/lever down, the meter should read close to zero…. Some cheap meters and cables they are supplied with will not show absolute zero. But it will be close.

If the meter reads close to zero before activating switch, the switch is stuck in closed position and faulty.

If it reads open (no change in meter reading compared to test leads not connected to anything including each other), then reads closed (or close to zero ohms) when it is pressed means the switch is working as intended.

This sounds simple to me, but if confused just ask further questions.

EDIT:

It’s unclear in any information I can find on your printer if it also takes a reading for open position. I don’t believe it does. Just to be safe, you can test that as well.

Just hook meter to C and NC poles of switch.

It will show opposite results. When not pressed it will show close to zero on meter. When pressed it will show open on meter.